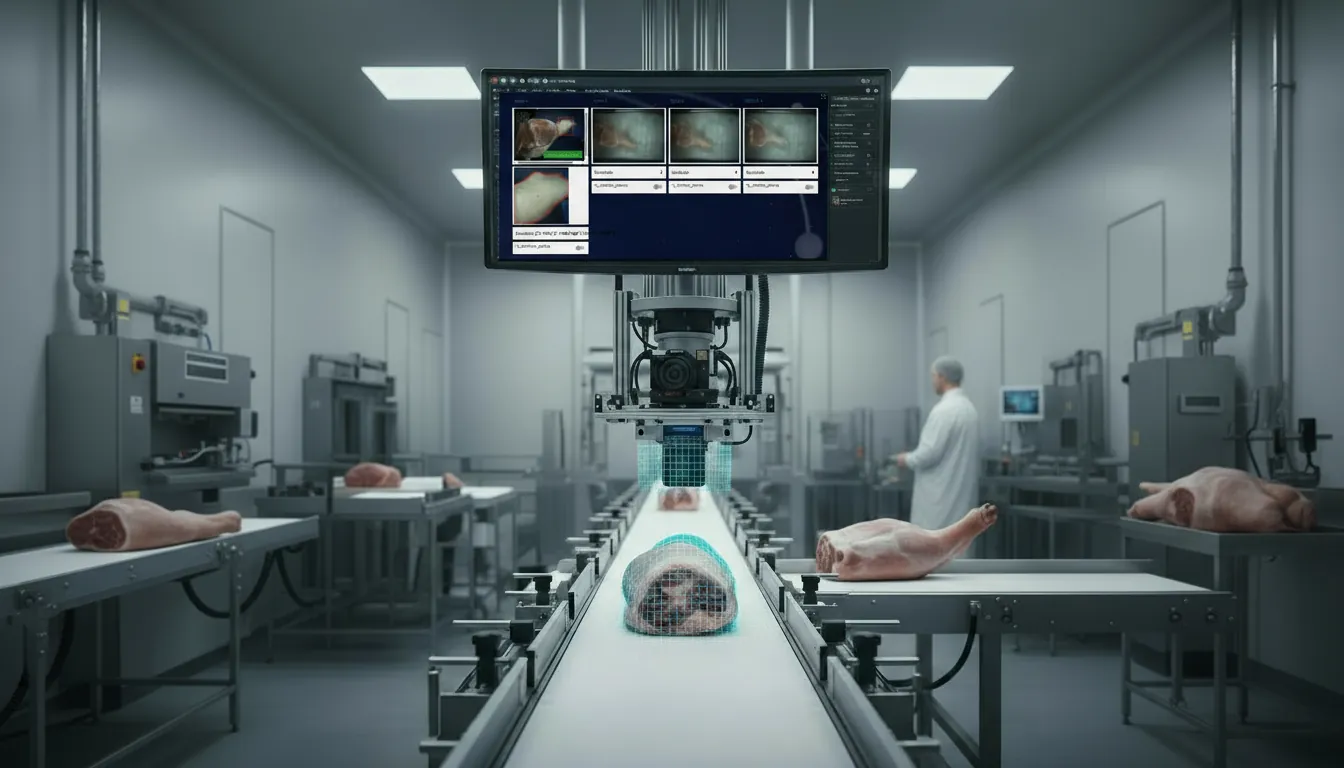

Rosepetal AI provides comprehensive quality control solutions for the food and beverage industry, ensuring product safety, consistency, and regulatory compliance through advanced computer vision and AI technology.

Get Started

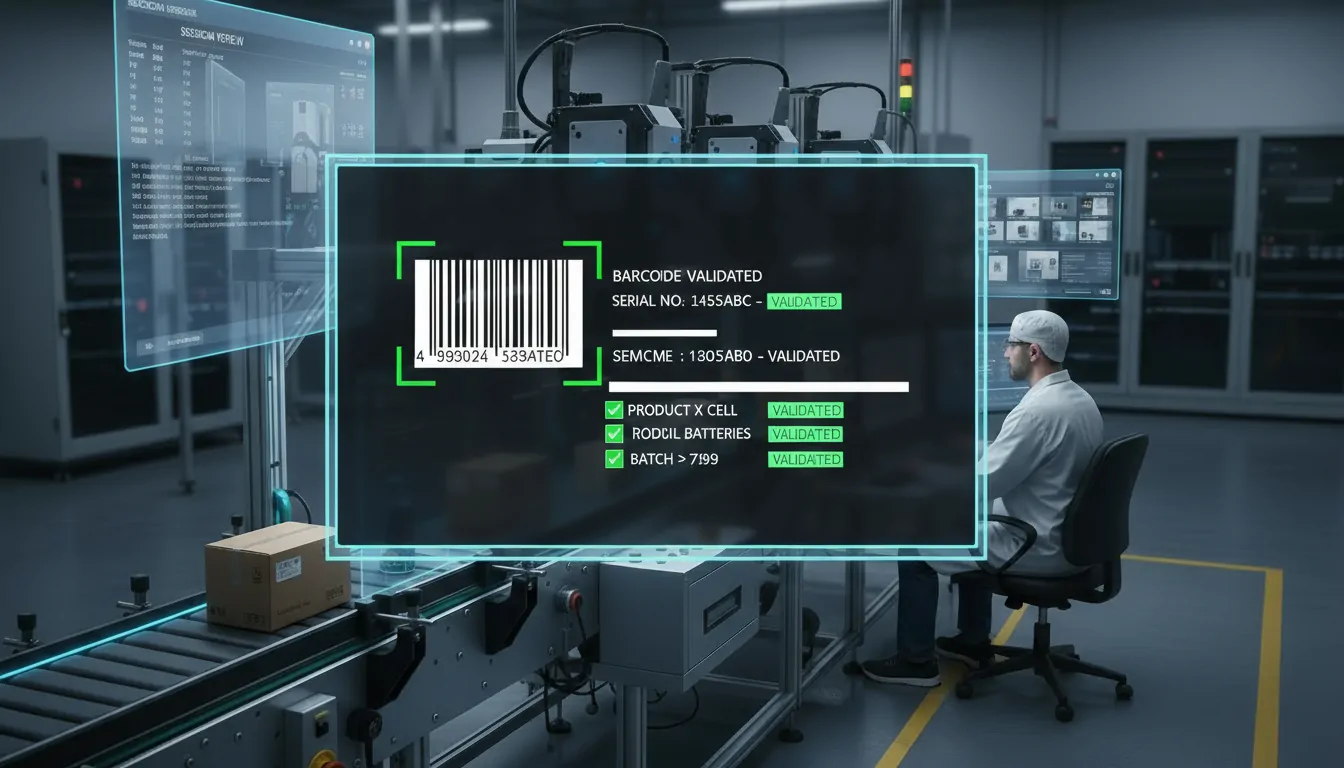

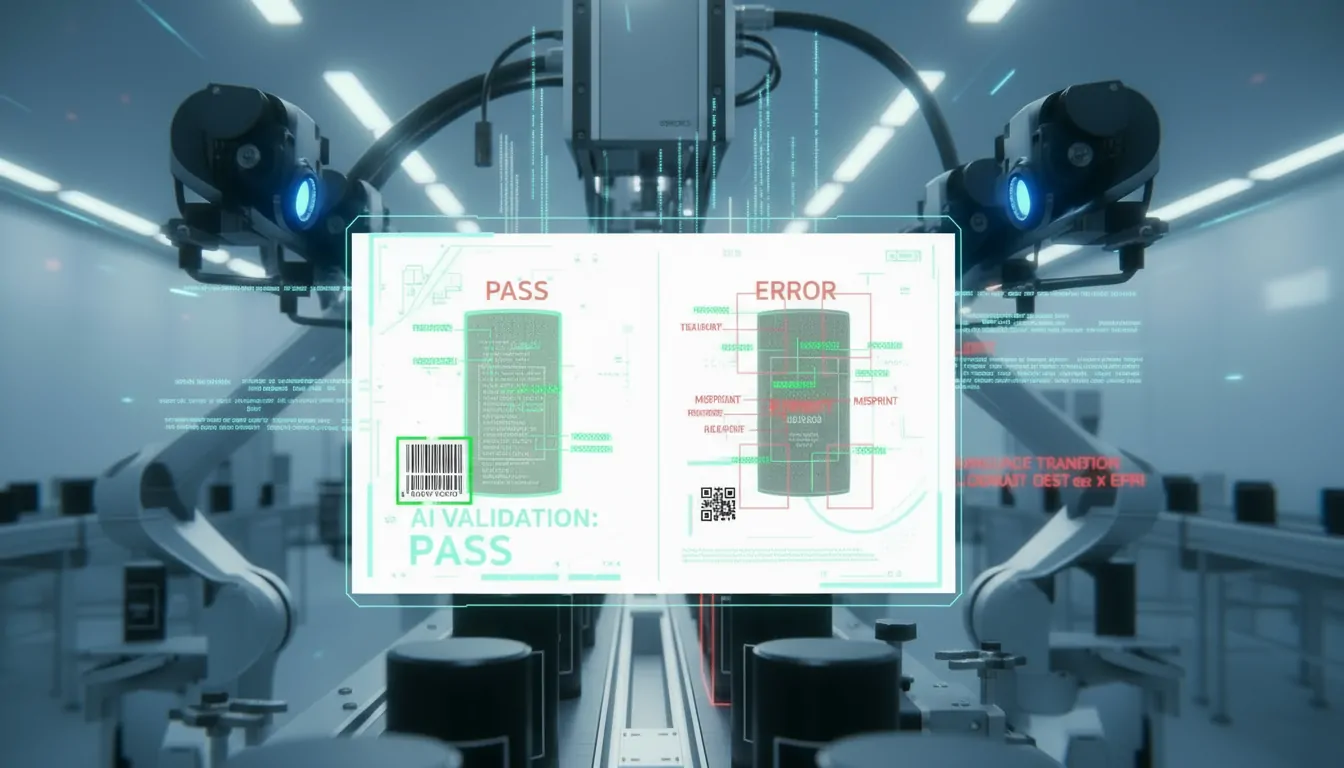

Ensure accurate labeling with AI-powered verification systems that check ingredients, nutritional information, expiry dates, and compliance with food safety regulations. Prevent costly recalls and protect brand reputation.

Identify product defects, packaging issues, seal integrity, cap alignment, and contamination in real-time. Analyze product size, color, and textures to maintain the highest quality standards.

Automatically verify fill levels in bottles, cans, and packages. Measure dimensions and volume to ensure consistency, meet specifications, and prevent product giveaway.

Detect foreign objects, contaminants, and anomalies in production lines to ensure food safety and consumer protection. Prevent contamination incidents before products reach consumers.

Validate ingredient quality at the receiving stage. Count, sort, and measure raw materials to ensure only the best inputs enter your production process.

Inspect packaging for damage, tears, dents, or deformation. Count items in cartons and verify packaging integrity before shipment to reduce returns and customer complaints.

A computer vision system designed to inspect bread loaves in real time, ensuring perfect size, shape, scoring, and structure consistency across production lines.

An advanced deep learning vision system for tuna can analysis—detecting contaminants, foreign materials, and production defects with near-perfect accuracy.

An AI-driven robotic guidance system for precise laser marking and verification in the food industry, ensuring consistent branding and full traceability in production lines.

A real case of zero tolerance for error in food industry label accuracy using AI vision technology.

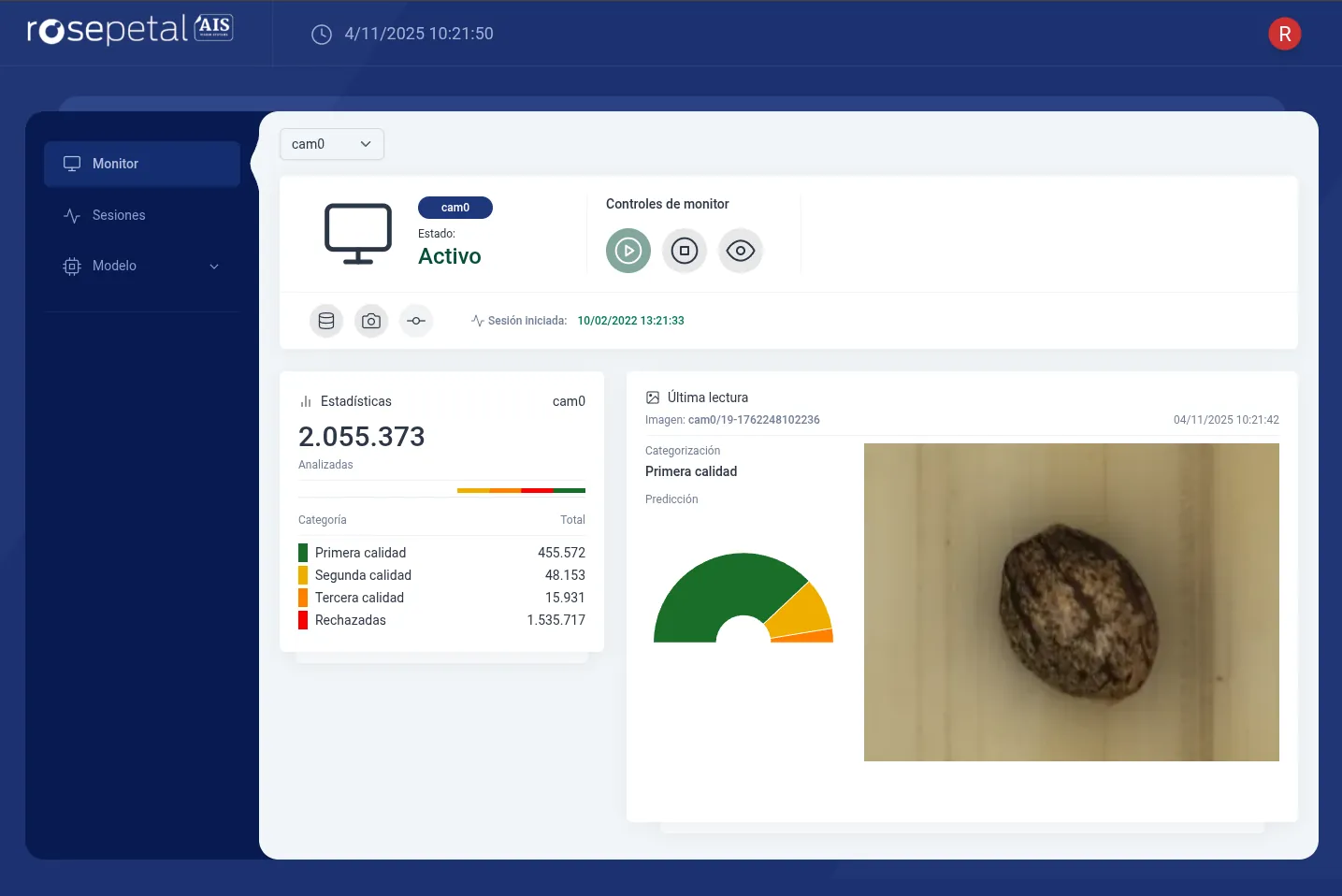

Argirella Nervosa optimized its seed production line with computer vision and deep learning, achieving fully automated quality control thanks to Rosepetal.

Specialized flow for reading and validating barcodes, serial numbers, and printed text on moving products, with capture and session-based review.

Generic flow for single or multi-camera projects, for applying models of any type, with session tracking, logs, capture, and adaptable settings page

Validate product labels for text accuracy, positioning, print quality using AI vision, including wrinkle, damage, and language validation checks

Specialized flow for detecting and counting products on conveyor belts, with real-time monitoring, image capture, and session review by label.

Automated flow for detecting, tracking, and analyzing stock levels using AI vision, with real-time monitoring, image capture, and ERP-ready session reporting.

From raw material receiving to final packaging, our AI-powered computer vision system monitors and automates quality control at every stage of your food and beverage production process.

Validate ingredient quality before production begins

Monitor production in real-time for optimal efficiency

Automated visual inspections at every checkpoint

Ensure packaging meets all standards and regulations

Maintain highest food safety standards

Last quality check before shipping

Detection Accuracy

Hours Saved Annually

Waste Reduction

Leading food processors have eliminated thousands of hours of manual sorting, reduced waste by up to 30,000 pounds, and prevented costly recalls by catching packaging flaws before products reach consumers.

Catch packaging flaws, labeling errors, and contamination before products reach consumers. Protect your brand reputation and avoid expensive recalls.

Minimize production waste by up to 30% through early defect detection and process optimization. Improve yield and reduce material costs.

Maintain compliance with food safety regulations through automated documentation and consistent quality checks. Meet HACCP, FDA, and other standards.

Unlike manual inspection, our AI never gets tired or distracted. Maintain consistent quality standards around the clock, every single day.

Deliver consistently high-quality products that meet customer expectations. Build consumer confidence and loyalty through reliable quality.

Track every product from raw materials to final packaging. Enable quick response to quality issues and maintain comprehensive production records.

Discover how Rosepetal AI can help you prevent recalls, reduce waste, and ensure consistent quality across your production line.