Deliver pharmaceutical excellence with Rosepetal AI's precision inspection systems. Our solutions ensure regulatory compliance, product safety, and quality assurance throughout the pharmaceutical manufacturing process.

Get Started

Automated inspection of blister packs to verify correct pill placement, detect missing tablets, identify color variations, and ensure complete packaging integrity throughout the production line.

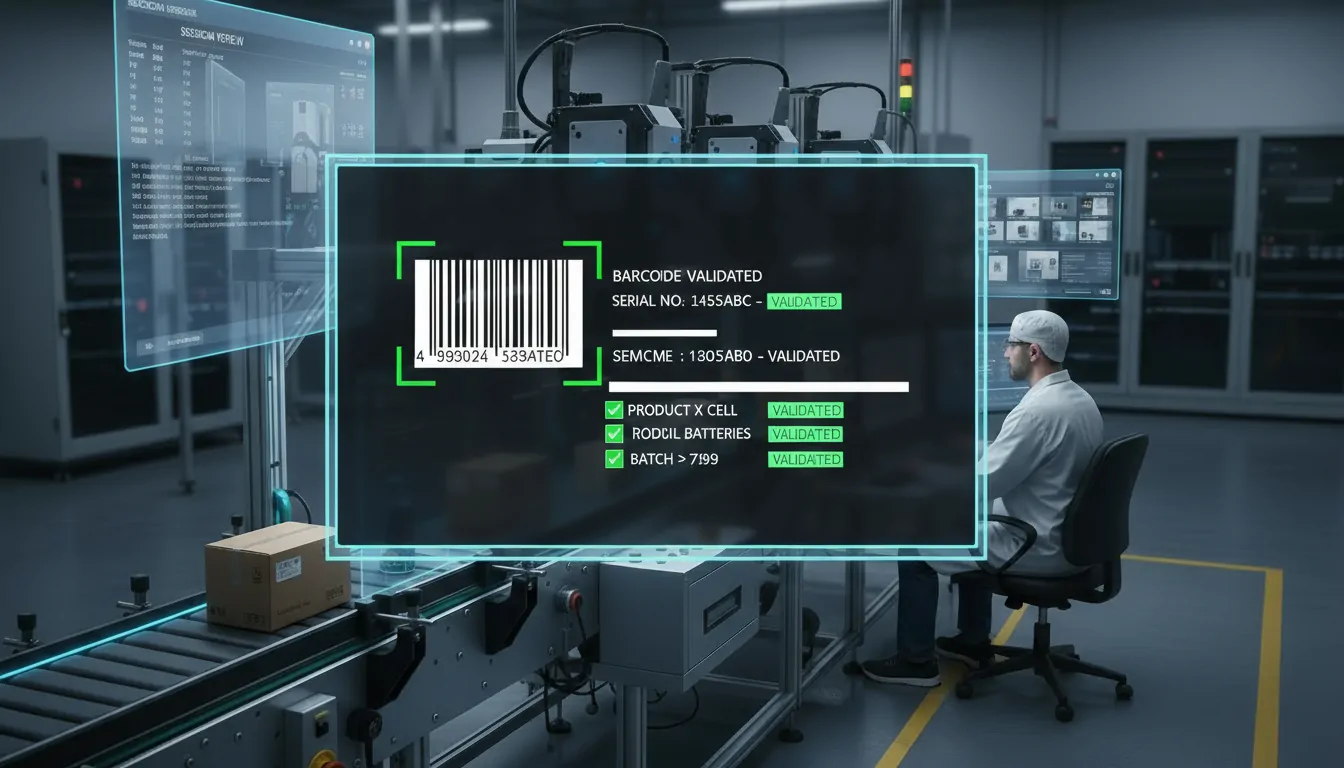

Ensure accurate pharmaceutical labeling with verification of barcodes, batch numbers, expiration dates, serialization codes, and regulatory information. Meet Track & Trace requirements and prevent counterfeit products.

Detect microscopic particles, hairline cracks, chips, and imperceptible micro-defects in vials and syringes. Verify fill levels and guarantee product safety, sterility, and quality.

Identify contaminants at every stage of production, from raw materials to finished products. Detect foreign particles, contamination, and cleanliness issues before they reach patients.

Comprehensive inspection of packaging integrity including seal quality, cap alignment, tamper-evidence verification, and damage detection to ensure product safety during distribution.

Monitor pharmaceutical equipment condition, track production processes in real-time, and identify process anomalies to maintain consistent quality and minimize downtime.

Specialized flow for reading and validating barcodes, serial numbers, and printed text on moving products, with capture and session-based review.

Generic flow for single or multi-camera projects, for applying models of any type, with session tracking, logs, capture, and adaptable settings page

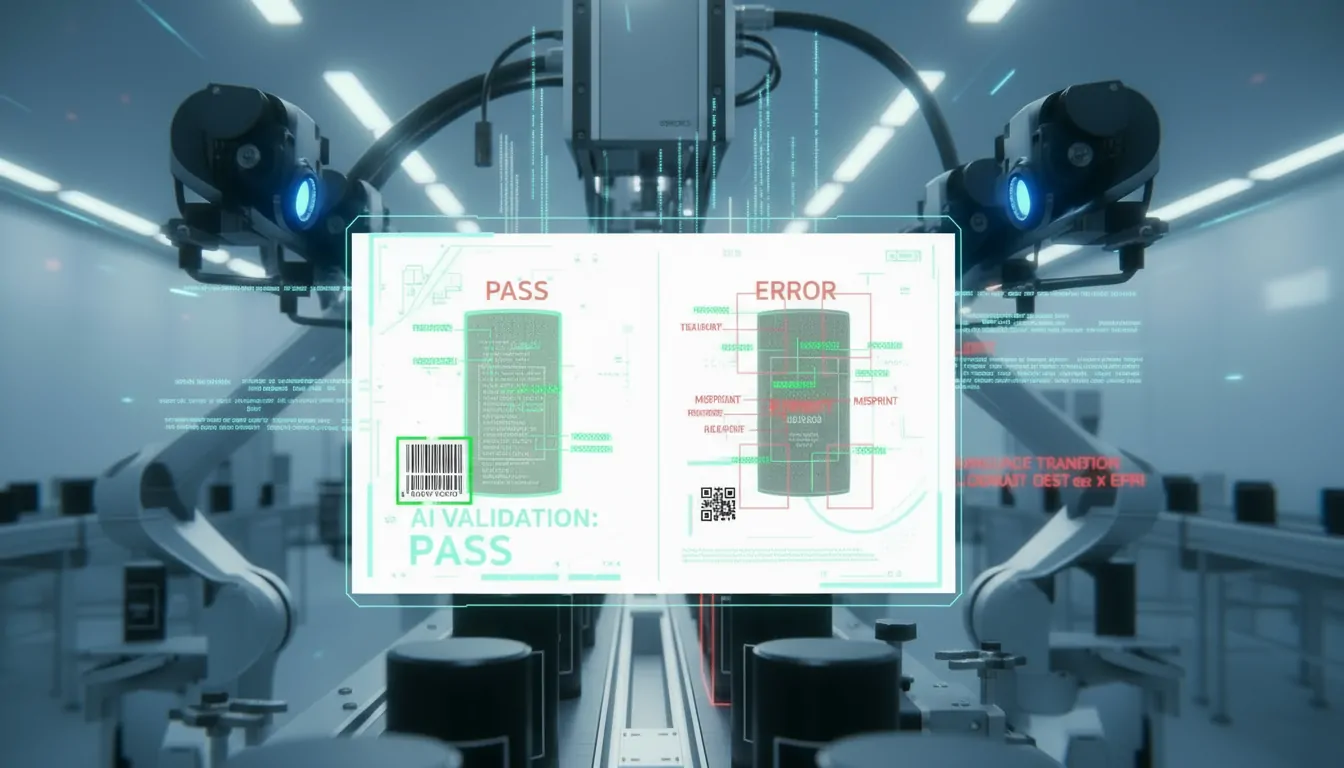

Validate product labels for text accuracy, positioning, print quality using AI vision, including wrinkle, damage, and language validation checks

Specialized flow for detecting and counting products on conveyor belts, with real-time monitoring, image capture, and session review by label.

Automated flow for detecting, tracking, and analyzing stock levels using AI vision, with real-time monitoring, image capture, and ERP-ready session reporting.

Catch quality issues early in pharmaceutical production with AI-powered inspection systems. From raw material receiving to final release, ensure the highest safety standards and regulatory compliance at every stage.

Validate pharmaceutical ingredients at receiving

Real-time oversight of manufacturing processes

Automated visual inspection at critical checkpoints

Comprehensive packaging inspection and validation

Regulatory compliance and traceability

Last quality gate before distribution

Regulatory Compliance

False Rejection Rate

Continuous Monitoring

Identify microscopic defects, hairline cracks, and contamination that are invisible to the human eye. Prevent defective products from reaching patients.

Maintain the highest safety standards through comprehensive contamination detection, packaging integrity verification, and quality control at every production stage.

Maintain compliance with FDA, EMA, and other pharmaceutical regulations. Automated documentation and full traceability for audits and inspections.

Verify serialization codes, track batch numbers, and ensure complete supply chain traceability to combat counterfeit pharmaceuticals and protect brand integrity.

Replace subjective manual inspections with consistent, objective AI-powered quality control. Reduce variability and improve detection accuracy significantly.

Track every pharmaceutical product from raw materials through production to distribution. Enable rapid batch recalls and comprehensive quality investigations.

Ensure patient safety, regulatory compliance, and operational excellence with Rosepetal AI's advanced quality control solutions.