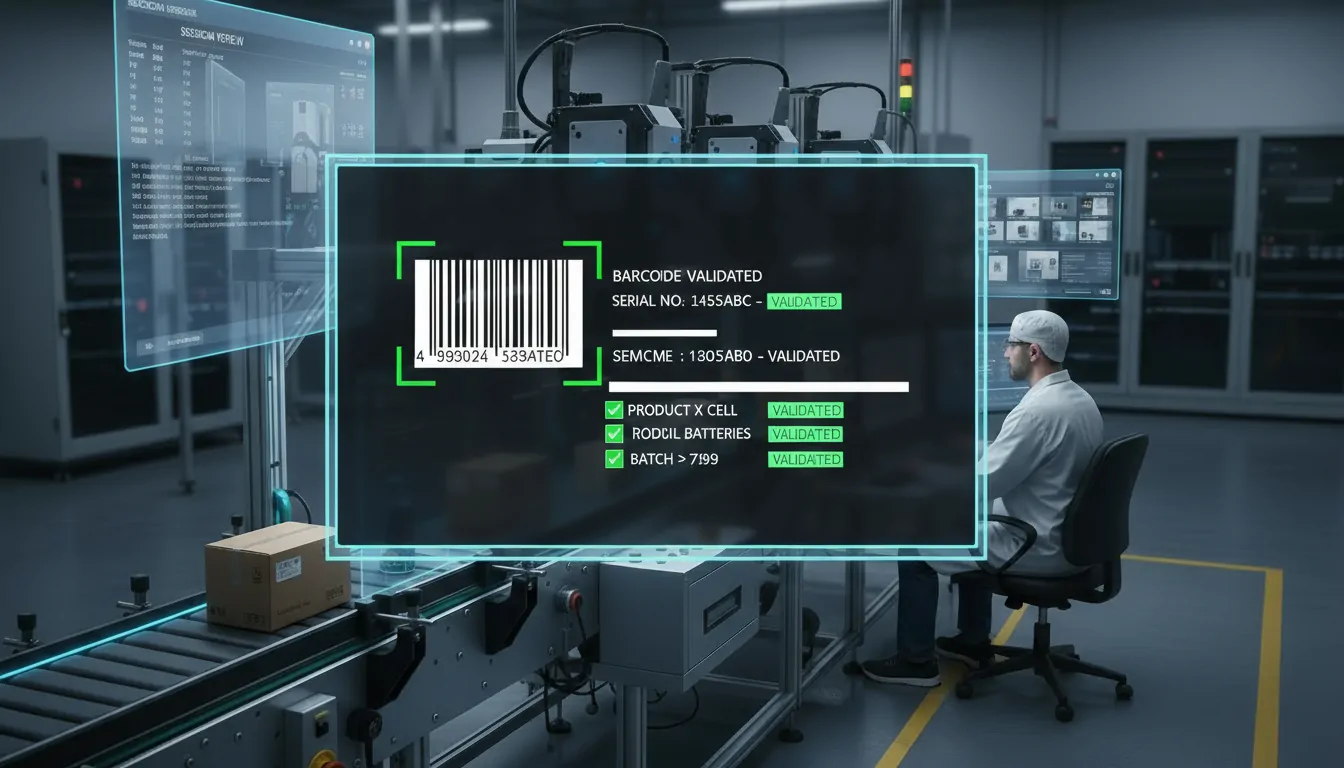

🧾 Barcode & OCR Recognition Flow

The Barcode & OCR Recognition Flow is a specialized computer vision pipeline for automatically reading, validating, and logging barcodes, QR codes, and printed text on products moving through production or packaging lines.

It provides real-time recognition, live monitoring, automatic image capture, and full session history with per-label traceability — making it ideal for quality control, logistics, and manufacturing trace systems.

🧠 Main Flow – Detection and Recognition Core

The Main Flow orchestrates the camera input, OCR/barcode decoding, and validation logic.

It supports multiple simultaneous cameras and models to detect and interpret codes or text under varied lighting and motion conditions.

Components

-

Camera Input:

Streams from industrial or IP cameras positioned along the line.

Each camera can be configured independently for focus zones, exposure, and capture rate. -

Detection Engine:

Performs simultaneous detection of barcodes (EAN, QR, DataMatrix, Code128, etc.) and OCR on printed regions.

Uses hybrid pipelines combining traditional decoding (e.g., ZBar, pyzxing) and neural OCR models (e.g., CRNN, TrOCR). -

Recognition Logic:

Extracts barcode content or text, validates it against reference templates or databases, and records results with timestamps.

Supports configurable parameters such as:- Minimum decoding confidence.

- Target label formats or prefixes.

- Auto-retry for partial or blurred detections.

-

Configuration:

Parameters can be tuned through the Config panel or API:- Camera alignment and regions of interest (ROI).

- Model type (OCR-only, barcode-only, or hybrid).

- Validation rules (e.g., must match SKU pattern).

- Triggers for image capture or logging.

Outputs

- Recognized text or code values with timestamp and camera ID.

- Validation result (valid / invalid / unreadable).

- Image capture trigger on every recognition event or error.

This module ensures high-accuracy recognition even in motion or low-quality print conditions.

🖥️ Monitor – Real-Time Visualization and Control

The Monitor subflow provides an interactive control panel for live viewing and operational status.

Features

- Live display of each camera feed with overlays showing detected barcodes or OCR bounding boxes.

- Dynamic visualization of recognition confidence, read frequency, and throughput.

- Error notifications for unreadable or missing codes.

- Real-time statistics panel showing valid/invalid ratios per product type or label.

- Start, stop, and reset controls for each recognition session.

The Monitor acts as the central supervision tool for line operators or engineers, providing both visual feedback and operational insights.

📸 Capture – Automatic Image Archiving

The Capture module stores image samples corresponding to each recognized or failed read event.

It works similarly to the Training subflow in the generic multicam system, but is specifically designed for OCR/barcode contexts.

Capabilities

- Automatic capture of each frame containing a recognized code or text region.

- Categorization by status (valid, invalid, unreadable) and type (barcode vs. OCR).

- Directory-based organization by date, camera, and label value.

- Dataset-ready structure for retraining recognition models or performing audits.

- Manual capture option from the Monitor for operator validation.

This ensures complete visual traceability of every recognition event, facilitating both debugging and quality audits.

📊 Sessions – History, Validation, and Review

The Sessions module logs every recognition session, aggregating all read data and captured frames for later inspection.

Functionality

- Session history: Lists all past recognition runs with start/end time, camera IDs, and total codes processed.

- Detailed results: Displays every decoded value, its validation result, and associated image capture.

- Image viewer: Allows browsing of captured frames grouped by label value or recognition status.

- Export: Download full session results in CSV format (including timestamp, camera, decoded value, confidence, and result).

- Integration: Optional connection to external ERP or MES systems for traceability and compliance.

Operators and engineers can visually inspect misreads or verify label consistency directly from the Sessions panel.

🧱 Interconnection Between Subflows

| Subflow | Purpose | Main Interactions |

|---|---|---|

| Main Flow | Detects and decodes barcodes/text | Sends results and captures to Monitor, Capture, and Sessions |

| Monitor | Real-time supervision | Controls session state and displays live recognition |

| Capture | Saves frames of detections and errors | Receives triggers from Main Flow |

| Sessions | Archives and exports all results | Aggregates logs and images from all modules |

💡 Typical Use Cases

- Automatic label and barcode validation in packaging lines.

- OCR-based serial number reading on manufactured parts.

- Verification of printed expiration dates or batch codes.

- Warehouse and logistics code scanning with camera-based systems.

- Regulatory compliance through full visual traceability of printed identifiers.

🧾 Summary

The Barcode & OCR Recognition Flow by Rosepetal AI offers an end-to-end vision system for automated barcode and text validation.

It unifies recognition, logging, and review in one modular environment — ensuring high accuracy, traceability, and easy integration into industrial and logistics workflows.

Ready to Deploy This Flow?

Contact our team to get started with this workflow. We'll help you integrate it into your production line and customize it to your specific needs.