Maintain product excellence and brand reputation with Rosepetal AI's automated quality control solutions. Our systems ensure every product meets your standards before reaching customers.

Get Started

Identify surface defects, scratches, dents, cracks, discoloration, and imperfections in consumer products and electronic components. Analyze product size, color, and textures to ensure premium quality standards.

Ensure correct assembly of complex products by verifying component placement, orientation, completeness, and proper alignment. Detect missing components and assembly errors in real-time on production lines.

Inspect packaging for proper sealing, damage detection, and appearance. Verify nutrition labels, product information, barcodes, and expiration dates to maintain brand standards and regulatory compliance.

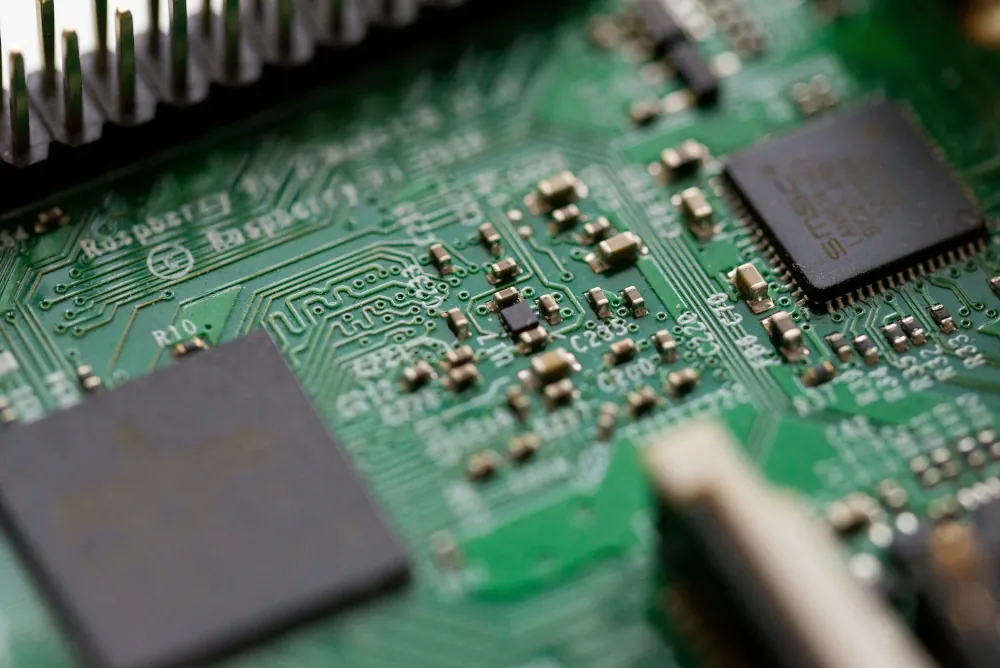

Automated optical inspection of printed circuit boards to detect soldering defects, component misalignment, missing parts, and quality issues. Ensure electronic products meet technical specifications.

Validate incoming material quality, measure dimensions and volume, count and sort components. Identify damaged or substandard materials before they enter production to reduce waste.

Comprehensive end-of-line inspection including visual appearance, packaging integrity, labeling accuracy, and counting items in cartons before shipment to prevent customer returns.

Specialized flow for reading and validating barcodes, serial numbers, and printed text on moving products, with capture and session-based review.

Generic flow for single or multi-camera projects, for applying models of any type, with session tracking, logs, capture, and adaptable settings page

Validate product labels for text accuracy, positioning, print quality using AI vision, including wrinkle, damage, and language validation checks

Specialized flow for detecting and counting products on conveyor belts, with real-time monitoring, image capture, and session review by label.

Automated flow for detecting, tracking, and analyzing stock levels using AI vision, with real-time monitoring, image capture, and ERP-ready session reporting.

From raw material receiving to final packaging, ensure premium quality at every stage of consumer product and electronics manufacturing. Reduce waste, prevent recalls, and elevate brand trust.

Quality validation at receiving stage

Real-time production monitoring

Automated visual inspection systems

Ensure proper product assembly

Packaging integrity and compliance

Pre-shipment quality verification

Defect Detection Rate

Faster Than Manual Inspection

Reduction in Returns

Leading consumer goods manufacturers achieve exceptional results by automating quality control with AI-powered computer vision, catching defects early and preventing expensive recalls.

Ensure only premium-quality products reach customers. Detect defects, packaging flaws, and quality issues before they impact your brand reputation and customer satisfaction.

Minimize production waste by catching quality issues early. Reduce material costs, improve production yield, and optimize manufacturing processes for maximum efficiency.

Catch packaging flaws, assembly errors, and product defects before they reach consumers. Avoid costly recalls, returns, and warranty claims through comprehensive quality control.

Inspect products at production line speed without slowing down manufacturing. AI-powered systems work 3x faster than manual inspection while maintaining higher accuracy.

Maintain uniform quality standards across all production lines and shifts. AI doesn't get tired, distracted, or inconsistent—delivering reliable results 24/7.

Gain actionable insights from quality data. Track defect patterns, identify production issues, and continuously improve manufacturing processes with comprehensive analytics.

Deliver premium quality products at production speed with AI-powered visual inspection that catches every defect.