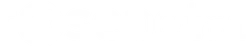

🏷️ Label Verification Flow

The Label Verification Flow is an advanced AI vision pipeline designed to inspect product labels for presence, position, orientation, condition, and text accuracy.

It ensures that every item leaving a production line meets visual quality standards — detecting missing or misaligned labels, wrinkles, scratches, and incorrect text or language.

Ideal for packaging, cosmetics, food, and pharmaceutical industries, this flow automates one of the most critical steps in visual quality control.

This pre-built flow automatically:

- Verifies label text accuracy against product specifications

- Checks label positioning and alignment

- Detects print quality issues (smudges, missing text, low contrast)

- Validates barcodes and QR codes

- Ensures compliance with regulatory requirements

🧠 Main Flow – Visual Inspection and Analysis

The Main Flow handles the full label inspection process: from image acquisition to multi-criteria evaluation.

It integrates object detection, OCR, and surface analysis to detect both physical defects and content inconsistencies.

Components

-

Camera Input:

Connects high-resolution cameras positioned along the labeling or packaging station.

Each camera is calibrated for lighting, perspective, and trigger timing to ensure consistent image capture. -

Detection and Verification Modules:

The flow performs several types of checks in a single inference pipeline:- Label Presence: Confirms that a label is present in the expected region.

- Label Position: Measures alignment, offset, and rotation relative to the defined template.

- Inverted Label Detection: Identifies upside-down or mirrored labels via pattern orientation.

- Wrinkle Detection: Detects surface deformation using texture gradients and contour irregularities.

- Scratch & Damage Detection: Highlights rips, tears, or abrasions on printed surfaces.

- Broken Borders: Detects incomplete or missing label edges.

- Text Reading (OCR): Extracts printed text inside the label for content validation.

- Language Validation: Verifies that detected text matches the expected language and character set.

-

Configuration:

All thresholds, templates, and label ROIs are adjustable through the Config API or UI:- Define label areas per camera

- Set tolerance for alignment and rotation

- Select detection modes (physical, textual, or both)

- Configure acceptable languages and encoding sets

Outputs

- Boolean and numeric metrics for each verification step (OK / NOK).

- Annotated frames with bounding boxes and highlights for detected issues.

- Triggered image captures for defective samples.

- Structured JSON logs sent to the Sessions module.

This module provides a full inspection pipeline ready for industrial automation lines.

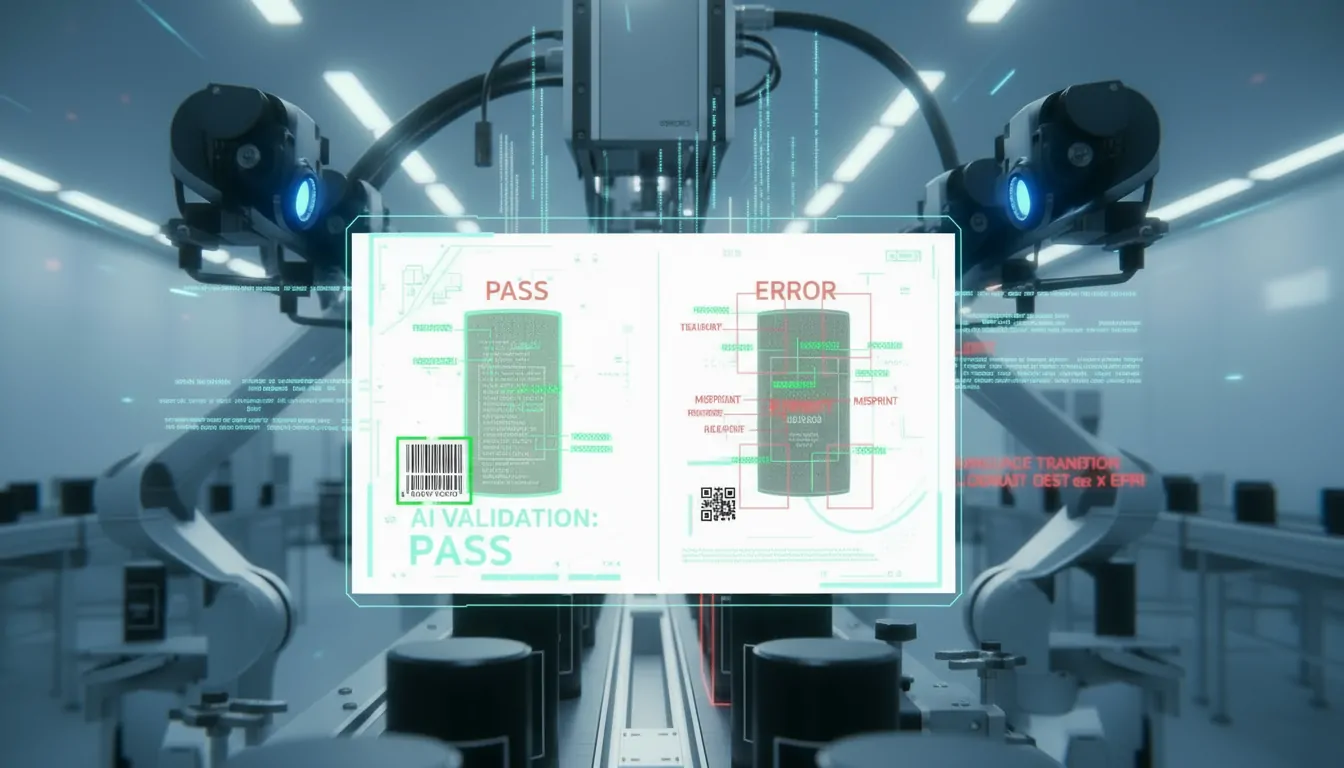

🖥️ Monitor – Real-Time Visualization and Control

The Monitor subflow acts as the inspection dashboard, giving operators a live overview of labeling quality.

Features

- Live camera streams with overlay annotations showing detected labels and warnings.

- Real-time defect indicators (missing, misaligned, wrinkled, damaged).

- Per-camera statistics: pass/fail ratio, label alignment score, average rotation.

- Manual re-check option for flagged frames.

- Start, stop, and reset buttons for each inspection line.

Monitor enables continuous quality assurance without stopping production.

📸 Capture – Defect and Sample Archiving

The Capture module automatically saves images related to label checks — both valid and defective.

It mirrors the functionality of the Training module from the generic flow, optimized for quality traceability.

Capabilities

- Automatic frame capture when:

- Label fails presence, alignment, or condition checks

- OCR or language validation fails

- Operator manually flags an item

- Image categorization by:

- Defect type (missing, misaligned, wrinkled, etc.)

- Camera ID and timestamp

- Product or batch ID

- Dataset-ready export for retraining or QA audits.

- Optional storage compression and auto-cleaning by retention policy.

Every defective or questionable label is visually documented for traceability and analysis.

📊 Sessions – Historical Records and Reports

The Sessions module compiles inspection results across production runs, offering a centralized record of quality checks and outcomes.

Functionality

- Session log: Tracks all inspection runs with metadata (date, product type, batch number).

- Defect summary: Aggregates statistics by defect type and frequency.

- Image review: Displays all captured defective labels, grouped by issue (e.g., “wrinkle,” “inverted,” “wrong language”).

- CSV export: Full run results including detection metrics, classification confidence, and timestamps.

- ERP/MES integration: Syncs inspection results, defect alerts, and quality KPIs with external manufacturing systems.

Sessions transform label inspection into quantifiable and reportable data for compliance and process optimization.

🧱 Interconnection Between Subflows

| Subflow | Purpose | Main Interactions |

|---|---|---|

| Main Flow | Performs label detection and analysis | Sends results and defect triggers to Monitor, Capture, and Sessions |

| Monitor | Supervises inspection in real time | Displays results and allows operator control |

| Capture | Stores defective and verified label images | Receives triggers from Main Flow |

| Sessions | Archives and exports inspection data | Aggregates all logs and captured frames |

💡 Typical Use Cases

- Presence and alignment verification of product labels on packaging lines.

- Quality control for bottles, cans, boxes, and pouches.

- Detection of printing or application defects (wrinkles, scratches, missing corners).

- OCR-based validation of expiration dates, batch numbers, or language compliance.

- Automated quality reports for traceability and regulatory validation.

Key Features

- Real-time inspection at production speed

- Multi-language support for text verification

- Customizable tolerance levels

- Integration with existing labeling systems

- Automatic reject mechanism for non-compliant products

🧾 Summary

The Label Verification Flow by Rosepetal AI offers a comprehensive, modular vision system for verifying labels on any product.

It combines deep-learning inspection, OCR, and image analytics to detect physical and textual defects in real time — ensuring labeling accuracy, visual quality, and compliance with international standards.

Ready to Deploy This Flow?

Contact our team to get started with this workflow. We'll help you integrate it into your production line and customize it to your specific needs.