Robotic Laser Marking and Reading System

An AI-driven robotic guidance system for precise laser marking and verification in the food industry, ensuring consistent branding and full traceability in production lines.

Success Story: Robotic Laser Marking and Reading System for Ham Legs

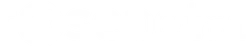

In the world of high-end food production, precision and consistency are essential. This project focused on automating the laser marking and identification of ham legs through a robotic guidance system powered by computer vision and AI.

The solution integrates orientation detection, dynamic positioning, and mark verification, delivering a fully automated and traceable marking process on a high-speed production line.

The Challenge

Our client, a leading producer of premium cured ham, needed a way to automatically mark and identify each ham leg during production.

Manual marking was slow, inconsistent, and depended heavily on operator experience. The key challenges included:

- Variable orientation of each ham leg on the conveyor

- Need for precise laser positioning on irregular surfaces

- High-speed throughput requirements on multiple production lines

- Mandatory traceability through code reading at the end of the process

The goal was to create a fully automated marking and verification system capable of adapting to product variability and maintaining zero defects in traceability.

The Solution: AI-Guided Robotic Laser Marking

We developed a robotic guidance system that combines AI vision, robotic control, and laser marking in a single integrated workflow.

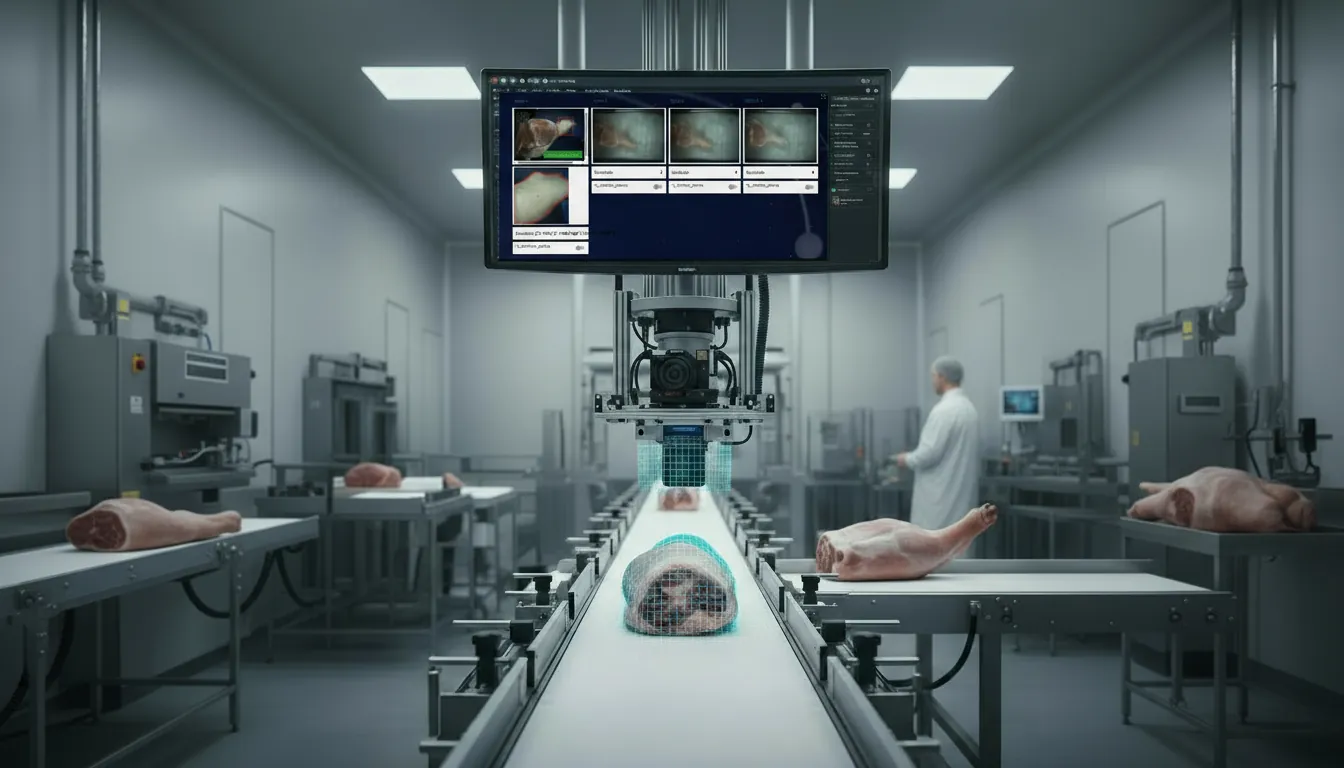

1. Orientation Detection

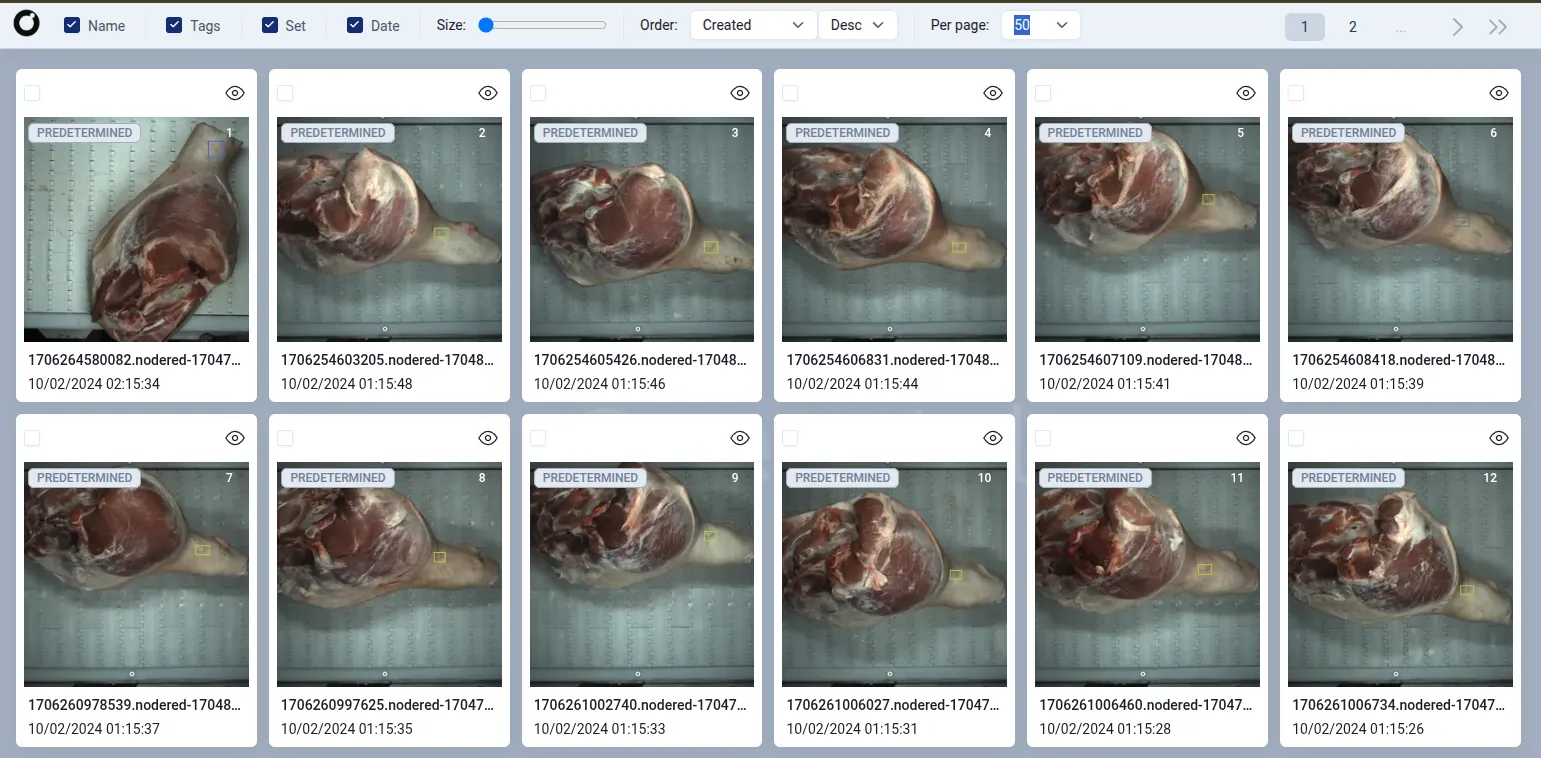

Each ham leg is first scanned using a 3D vision system that detects its exact orientation.

Based on this information, the product is routed to one of several conveyor lines optimized for that orientation.

2. Optimal Marking Point Selection

Once positioned, the system analyzes the leg’s geometry to identify the optimal point for laser marking.

The robot adjusts its trajectory dynamically, ensuring consistent and legible marking regardless of surface irregularities.

3. Laser Marking Execution

The robot-mounted laser performs the marking operation with sub-millimeter precision, encoding product data, batch information, or branding logos directly onto the surface.

4. Mark Reading and Validation

At the end of the line, a vision-based verification system reads and validates each marking.

This ensures that every product is correctly marked and traceable, with automatic rejection of any item that fails validation.

Results and Impact

The implementation of this system transformed the client’s marking process:

- 99.8% marking accuracy across all production lines

- 100% traceability with automatic mark reading at line end

- Throughput increased by 35% due to reduced manual handling

- Zero product rework for incorrect or missing marks

- Payback in less than 10 months through reduced labor and error elimination

✅ Key Results

- Robotic precision marking on complex organic surfaces

- Complete end-to-end automation: orientation → marking → verification

- AI-driven adaptability to product variability

- Reliable operation in a demanding industrial environment

- Enhanced traceability and brand consistency

Industry Significance

This project demonstrates how AI and robotics can bring smart automation to artisanal food production processes.

By integrating deep learning vision, robotic control, and laser technology, we enable producers to maintain craftsmanship standards while achieving industrial-level precision and reliability.

Technologies applied: Computer vision, robotic guidance, laser marking, deep learning, real-time verification

Sector: Food processing and industrial automation

Client: Confidential (premium cured ham producer)

Solution: Rosepetal AI Vision and Robotic Marking System