Rosepetal AI delivers advanced computer vision solutions for automotive manufacturing, ensuring quality, precision, and efficiency across every stage of vehicle production from component inspection to final assembly.

Get Started

Detect surface imperfections, scratches, dents, paint defects, and assembly errors in real-time. Maintain the highest quality standards across all vehicle components and finished products.

Verify that all components are present, correctly positioned, and properly assembled. Identify missing parts, misaligned components, and installation errors before they reach the next stage.

Inspect weld seams for consistency, strength, and defects. Detect incomplete welds, porosity, and other weld defects that could compromise structural integrity.

Analyze paint quality, color consistency, thickness, and surface finish. Detect runs, sags, orange peel, and other coating defects across all painted surfaces.

Verify safety labels, VIN numbers, and identification markings are accurate, correctly positioned, and clearly legible. Ensure regulatory compliance and traceability.

Monitor production equipment for signs of wear, misalignment, and potential failures. Detect blockages, predict maintenance needs, and prevent unexpected downtime.

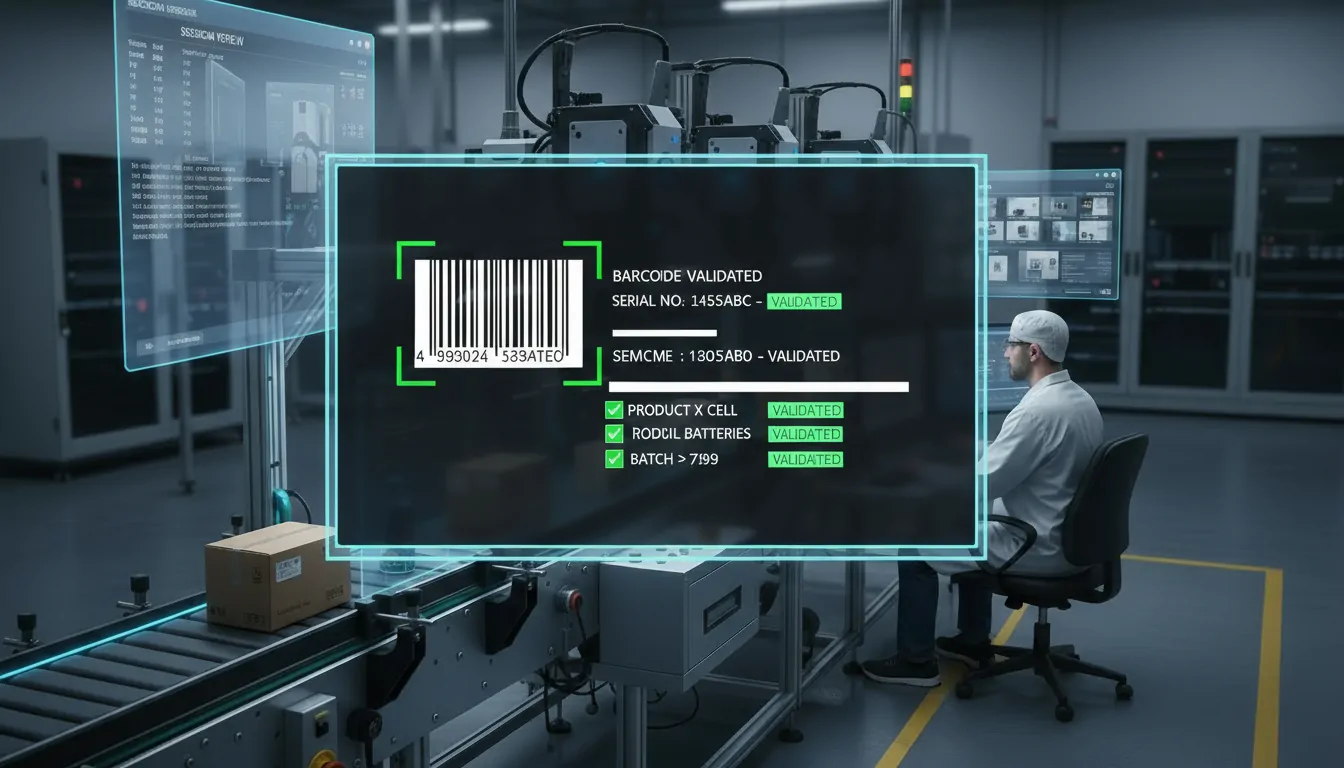

Specialized flow for reading and validating barcodes, serial numbers, and printed text on moving products, with capture and session-based review.

Generic flow for single or multi-camera projects, for applying models of any type, with session tracking, logs, capture, and adaptable settings page

From incoming parts inspection to final vehicle quality control, our AI-powered computer vision system monitors and automates quality checks at every stage of automotive manufacturing.

Validate component quality before assembly

Real-time monitoring of assembly operations

Ensure structural integrity of welds

Verify paint finish and coating quality

Comprehensive vehicle inspection before shipping

Predictive maintenance for production equipment

Saved Annually

Defect Detection Rate

Reduction in Inspection Time

Leading automotive manufacturers have saved millions by automatically detecting defects on production lines, preventing costly recalls, and reducing inspection time by up to 40% while maintaining superior quality standards.

Detect surface imperfections, assembly errors, and component defects before they reach customers. Avoid expensive recalls and warranty claims.

Predict equipment maintenance needs and prevent unexpected breakdowns. Minimize downtime and maintain consistent production flow.

Verify safety labels, monitor safety protocols, and maintain compliance with automotive industry standards and regulations.

Monitor production quality in real-time across all assembly lines. Identify and address issues immediately before they escalate.

Automate manual inspection processes and reduce labor costs by up to 40% while improving accuracy and consistency.

Track every component from supplier to final assembly. Enable quick response to quality issues and maintain comprehensive production records.

Discover how Rosepetal AI can help you prevent defects, reduce costs, and ensure consistent quality across your entire production line.