AI-Based Tuna Can Classification and Defect Detection

An advanced deep learning vision system for tuna can analysis—detecting contaminants, foreign materials, and production defects with near-perfect accuracy.

Success Story: AI-Based Tuna Can Classification and Defect Detection

In the seafood processing industry, ensuring the purity and safety of canned tuna is critical. Even the smallest foreign particle—be it metal, plastic, or bone—can compromise quality, safety, and brand reputation.

To address this challenge, our client, a leading tuna processing and packaging company, adopted Rosepetal’s AI vision and deep learning technology for real-time inspection and classification.

The Challenge

Traditional visual inspection methods—manual or semi-automated—were unable to detect subtle impurities in tuna meat.

The client needed a non-invasive, high-speed inspection system capable of identifying multiple types of contaminants and irregularities before sealing the cans.

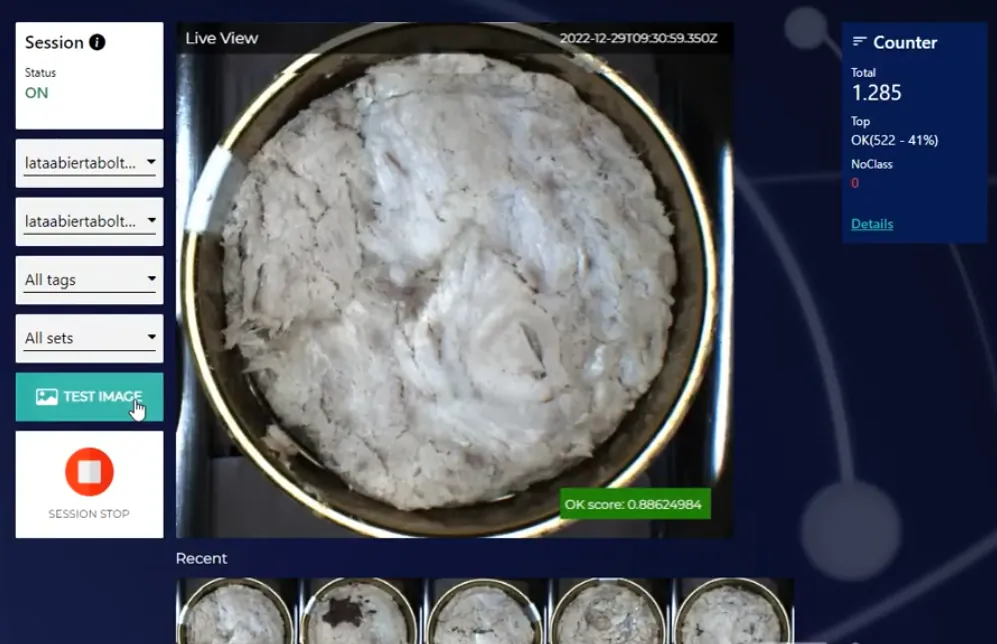

The system needed to classify and detect:

- Carton (packaging material residues)

- Bones (Espinas)

- Metal fragments

- Paper

- Skin residues (Piel)

- Plastics

- Dark tissue (Sangacho)

- Empty cans

Additional challenges included:

- High throughput production lines (up to 250 cans per minute)

- Moist, reflective surfaces that distort visual readings

- Need for full automation with minimal operator intervention

The Solution: AI Vision for Tuna Can Analysis

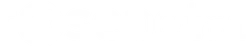

We implemented a custom deep learning classification system using Rosepetal Vision AI, specifically trained for canned seafood inspection.

1. Multi-Class Detection

Each can is analyzed through multiple vision checkpoints equipped with high-speed cameras and edge-AI processors.

The system classifies every unit into one of the defined categories—carton, bones, metal, paper, skin, plastics, dark tissue, or empty—with precision greater than 99%.

2. Real-Time Sorting

The inspection data is instantly processed on the production line.

Cans identified with foreign materials or incorrect content are automatically diverted, ensuring only compliant units proceed to sealing and labeling.

3. Adaptive Learning

The AI model continuously learns from new samples, adapting to variations in product color, texture, and lighting—eliminating the need for manual recalibration.

4. Seamless Integration

The system integrates directly with existing conveyors and production control systems, maintaining line speeds without downtime.

Results and Impact

After deployment, the client achieved remarkable improvements in quality control and process efficiency:

- 99.95% detection accuracy across all contaminant categories

- Zero non-compliance incidents reported since implementation

- 35% reduction in manual inspection costs

- Continuous 24/7 operation with minimal maintenance

- Payback period under 9 months

The automated inspection not only enhanced product safety and brand reliability, but also optimized data traceability, allowing complete digital logging of each can inspected.

✅ Key Results

- Multi-class detection of 8 defect and contamination types

- High-speed, real-time inspection with AI-based accuracy

- Automatic rejection of defective cans

- Improved safety compliance and production efficiency

- Seamless integration into existing factory automation systems

Industry Significance

This implementation marks a major step forward in food safety automation.

By combining deep learning, industrial vision, and real-time decision systems, the solution provides an unprecedented level of reliability in canned food inspection—helping manufacturers meet global quality standards while maintaining competitive production speeds.

Technologies applied: Deep learning, computer vision, real-time AI classification, edge processing, quality control automation

Sector: Seafood processing and packaging

Client: Confidential (Tuna canning producer)

Solution: Rosepetal AI Vision Inspection and Classification System