Transform your entire manufacturing operation with Rosepetal AI's comprehensive computer vision solutions. From raw material inspection to logistics, automate quality control, optimize processes, and ensure safety across every department.

Get Started

Detect surface imperfections, cracks, dents, scratches, and anomalies in real-time. Analyze product variations in color, texture, and size to maintain consistent quality standards across all production lines.

Identify production bottlenecks, line jams, and inefficiencies in real-time. Measure cycle times, optimize workflows, and control machinery to improve manufacturing yield and throughput.

Track inventory levels of raw materials and finished products automatically. Monitor stock levels, optimize storage, scan barcodes, and generate alerts when inventory reaches critical thresholds.

Monitor equipment status and detect performance anomalies before failures occur. Catch foreign objects in machinery, identify wear and tear patterns, and schedule proactive maintenance to reduce unexpected downtime.

Ensure worker safety by monitoring protective gear usage, detecting hazardous materials, identifying gas leaks, and tracking personnel in restricted zones. Maintain compliance with safety regulations automatically.

Verify correct component presence and assembly. Count parts automatically, sort components, guide robotic systems, and ensure specification accuracy throughout the manufacturing process.

A four-camera vision system for real-time inspection of cables, detecting geometric, surface, and conductor defects with AI precision in high-speed manufacturing lines.

An 8-camera 360º computer vision system for the inspection of metal containers, detecting curling and triple-seam defects, and verifying the presence of ear tabs in real time.

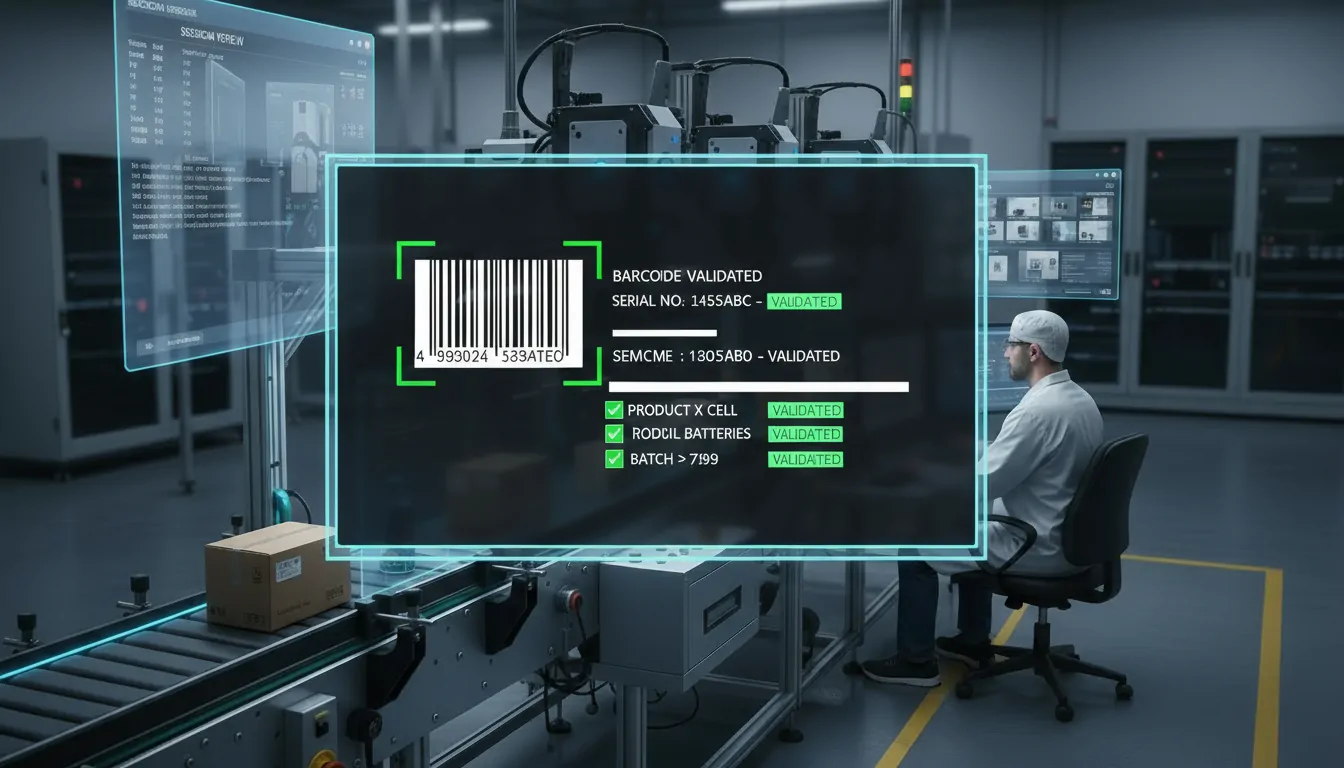

Specialized flow for reading and validating barcodes, serial numbers, and printed text on moving products, with capture and session-based review.

Generic flow for single or multi-camera projects, for applying models of any type, with session tracking, logs, capture, and adaptable settings page

Specialized flow for detecting and counting products on conveyor belts, with real-time monitoring, image capture, and session review by label.

Deploy AI-powered visual intelligence throughout your entire manufacturing operation, from procurement to logistics, ensuring quality, efficiency, and safety at every stage.

Inspect and validate incoming materials

Guide and optimize automated processes

Comprehensive quality inspection systems

Ensure workplace safety compliance

Predictive equipment maintenance

Track and optimize inventory flow

Reduction in Manual Tracking

Lower Return Rates

Annual Cost Savings

Leading manufacturers have achieved dramatic improvements through AI-powered vision systems: logistics companies reduced manual inventory tracking by 90%, building material suppliers lowered customer returns by 60%, and automotive manufacturers saved over $8 million annually by detecting production line defects.

Maximize production output by identifying bottlenecks, optimizing processes, and reducing defects throughout the manufacturing line.

Predict maintenance needs before failures occur. Monitor equipment performance and schedule proactive maintenance to minimize unexpected shutdowns.

Automate manual inspections, reduce waste, optimize inventory, and improve efficiency to significantly lower operational expenses.

Get instant visibility into production metrics, quality issues, and operational bottlenecks. Make data-driven decisions in real-time.

Automatically monitor safety compliance, detect hazardous conditions, and ensure workers wear proper protective equipment at all times.

Implement computer vision throughout procurement, automation, quality, safety, maintenance, inventory, and logistics for complete operational transformation.

Discover how Rosepetal AI can automate quality control, optimize processes, and reduce costs across your entire manufacturing operation.