AI Vision System for Pharmaceutical Bottle Inspection

A computer vision solution for pharmaceutical packaging lines, verifying label presence, position, and quality, cap integrity, and barcode readability in real time.

Success Story: AI Vision System for Pharmaceutical Bottle Inspection

In the pharmaceutical industry, packaging accuracy is critical — not only for regulatory compliance but also for patient safety.

Even minor labeling or sealing errors can lead to product recalls, loss of traceability, and compliance risks.

To guarantee the highest quality standards, a leading pharmaceutical manufacturer implemented a Rosepetal AI Vision System to automate inspection of pill bottles on their production line.

The Challenge

The client needed a fully automated system capable of inspecting every bottle in real time, detecting any visual or structural defect before packaging and labeling.

Traditional inspection methods based on sampling were insufficient for full-line verification, especially for high-speed production lines exceeding 200 bottles per minute.

The main inspection requirements included:

- Presence of the main label

- Position and alignment of the main label

- Detection of inverted labels

- Wrinkles or air bubbles in the label

- Scratches or surface damage on the label

- Presence of the cap

- Cap height and tilt verification (to confirm proper sealing or threading)

- Barcode reading and verification for traceability

The Solution: Rosepetal AI Pharmaceutical Bottle Inspection System

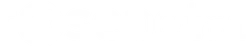

Rosepetal AI designed and deployed a 360º computer vision system tailored for cylindrical containers such as pill bottles.

The system combines high-speed cameras, LED illumination, and AI-powered defect classification for comprehensive inspection of every product.

1. 360º Bottle Inspection

Four synchronized cameras capture a full 360º view of each bottle.

This ensures complete label coverage and accurate detection of missing, inverted, or misaligned labels, even at high production speeds.

2. Label Quality Verification

Using deep learning algorithms, the system detects:

- Wrinkles, folds, or bubbles under the label surface

- Scratches, abrasions, or missing print elements

- Incorrect orientation or label skew exceeding tolerance thresholds

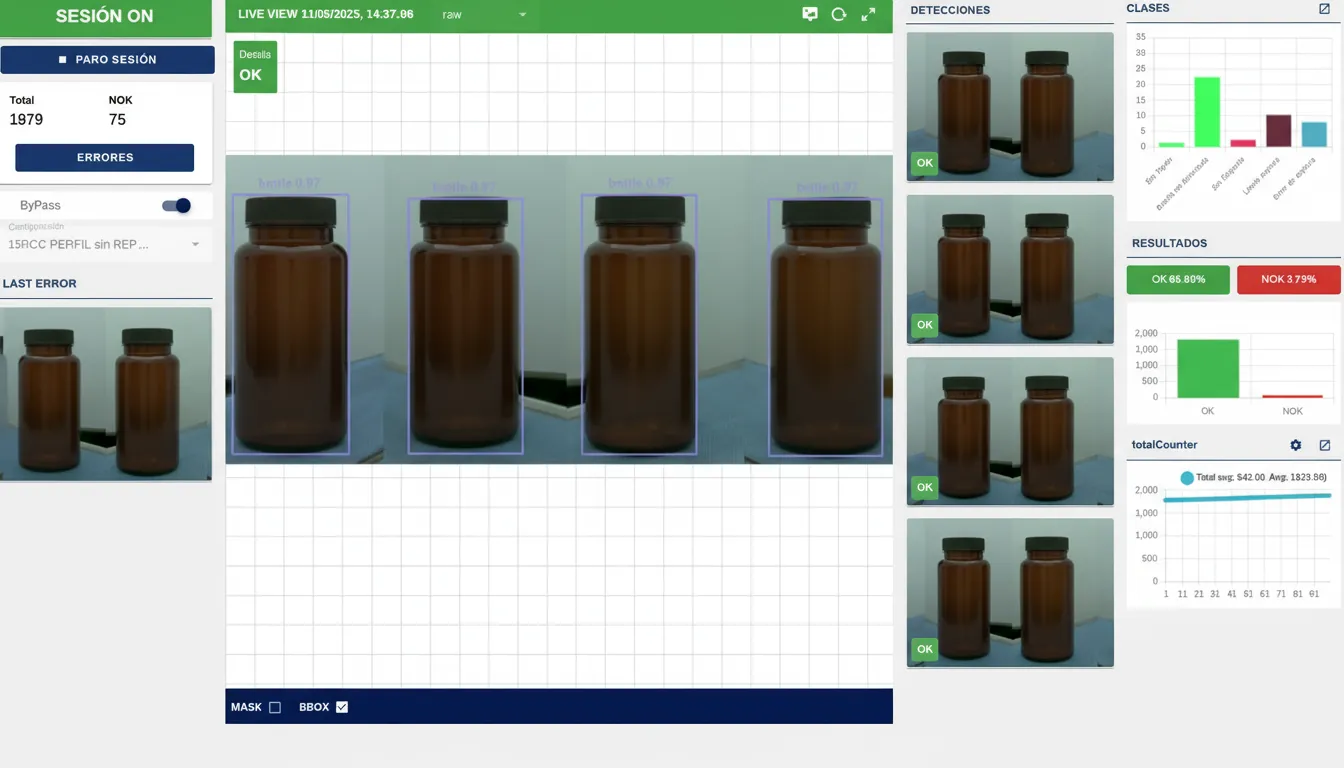

3. Cap Presence and Tightness Check

A top-view camera and 3D laser triangulation measure cap height and inclination, verifying correct thread engagement and closure torque indirectly through geometry.

4. Barcode Reading and Validation

Each bottle’s barcode is read using OCR and code verification algorithms.

Data is automatically compared to production orders and stored for traceability and serialization compliance (FDA 21 CFR Part 11 ready).

5. Real-Time PLC Integration

When a defect is detected, the system sends a signal to the PLC to automatically reject the defective bottle.

All inspection results are displayed on a user-friendly HMI panel, where operators can:

- View real-time defect images

- Adjust inspection sensitivity

- Create, modify, and load inspection “recipes” for different products

Results and Impact

After implementing the Rosepetal AI Vision System, the client achieved:

- 100% in-line inspection coverage

- 99.9% accuracy in label and cap verification

- Traceability and serialization compliance across all batches

- 35% reduction in manual inspection costs

- Zero customer complaints related to labeling or sealing defects

- Return on investment in 8 months

The system now operates 24/7, ensuring consistent product integrity and compliance with pharmaceutical packaging standards.

✅ Key Results

- Verification of label presence, position, and orientation

- Detection of wrinkles, scratches, and surface defects

- Cap sealing analysis through height and tilt measurement

- Barcode reading and data validation for traceability

- Automatic rejection and PLC integration

- Configurable HMI panel for visualization and recipe management

Industry Significance

This case demonstrates how AI vision systems are reshaping quality assurance in pharmaceutical manufacturing.

By combining multi-camera inspection, deep learning analytics, and PLC automation, Rosepetal AI helps ensure every product leaving the line meets strict regulatory and quality standards — protecting both patients and brand integrity.

Technologies applied: Deep learning, computer vision, barcode reading (OCR), 3D geometry measurement, PLC integration

Sector: Pharmaceutical packaging and healthcare manufacturing

Client: Confidential (Pharmaceutical packaging company)

Solution: Rosepetal AI Vision System for Pharmaceutical Bottle Inspection