360º AI Vision System for Metal Container and Ear Tab Inspection

An 8-camera 360º computer vision system for the inspection of metal containers, detecting curling and triple-seam defects, and verifying the presence of ear tabs in real time.

Success Story: 360º AI Vision System for Metal Container and Ear Tab Inspection

In the metal packaging industry, precision and integrity are non-negotiable.

Even a minor defect in the curling, triple seam, or ear tab presence can lead to leakage, loss of hermeticity, or rejection by the end customer.

To address this challenge, a leading container manufacturer partnered with Rosepetal AI to implement an AI-powered 360º vision inspection system for real-time quality control.

The Challenge

The client needed to guarantee defect-free production across millions of containers per month. Manual sampling was slow and unreliable for detecting microscopic curling or seam defects, and verifying ear tab presence was especially difficult at high speeds.

The goals of the new system were:

- To detect curling defects and irregular edges

- To verify triple seam integrity across the full circumference

- To ensure presence and alignment of ear tabs on every container

- To automatically reject defective units without stopping production

The Solution: Rosepetal AI 360º Container Inspection System

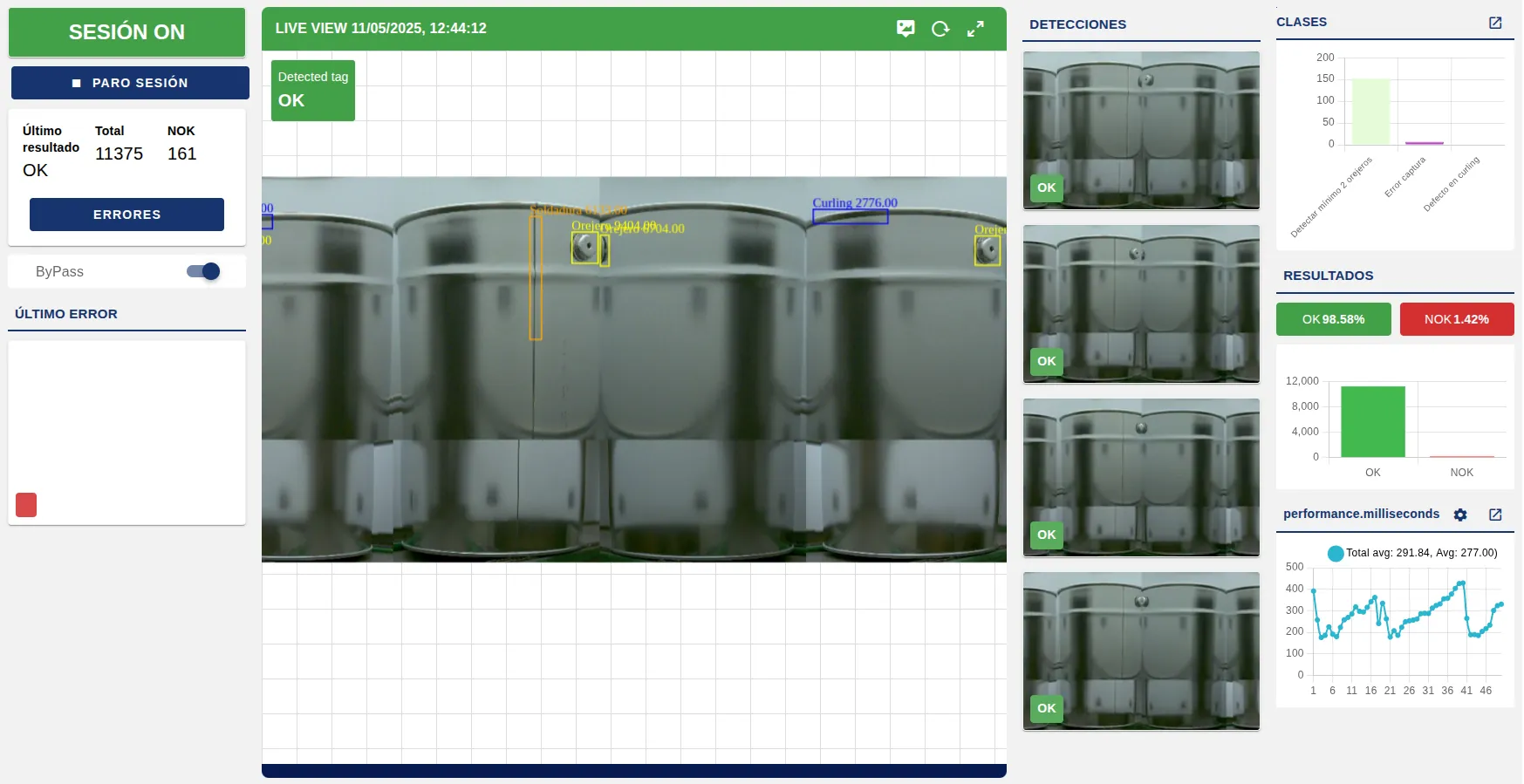

The solution designed by Rosepetal AI integrates 8 synchronized cameras, providing two full 360º inspections in vertical planes.

This configuration allows complete visualization of both the upper and lower seam regions of each container as it moves along the production line.

1. Full 360º Multi-Camera Inspection

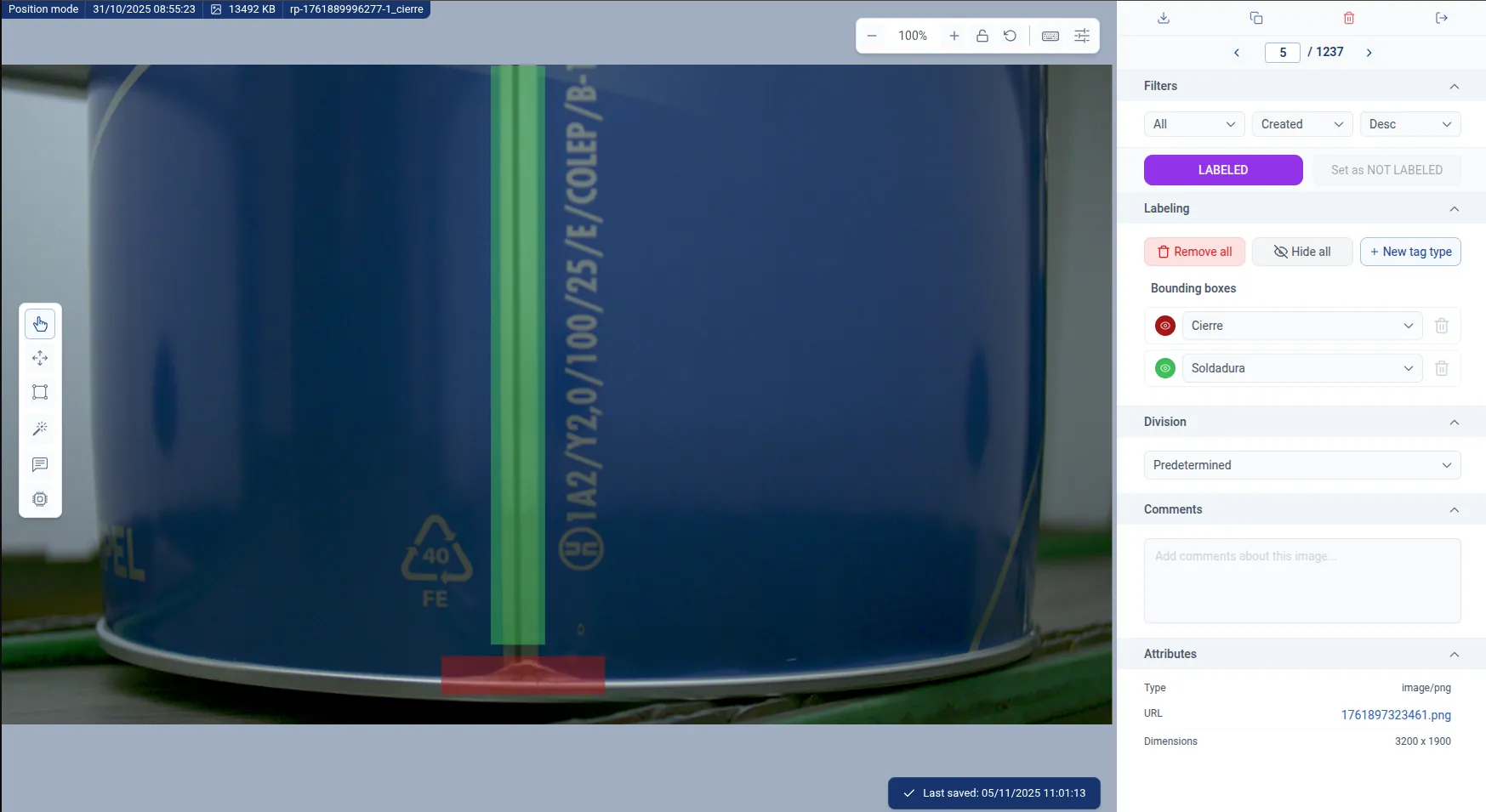

Eight high-resolution cameras capture every angle of the container, creating a composite cylindrical view that allows the AI to evaluate geometric and surface consistency with micrometric precision.

2. Curling and Seam Defect Detection

Deep learning algorithms analyze the curling geometry and triple-seam profile, identifying:

- Flattened or incomplete curling

- Excess or insufficient overlap

- Deformations or gaps in the sealing area

These anomalies are classified by severity and flagged in real time.

3. Ear Tab Presence and Position Verification

A separate AI module detects and verifies the presence and correct position of ear tabs using shape and contrast analysis.

Any missing or misaligned ear tab automatically triggers a rejection signal.

4. PLC Integration and Defect Ejection

When a defect is detected, the system sends an instant digital signal to the machine’s PLC, which controls the automatic ejection of the defective container without slowing down the line.

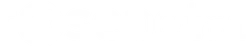

5. Operator Interface and Control Panel

The solution includes a standardized HMI control panel that allows operators to:

- Visualize inspection results in real time

- Adjust sensitivity levels for each defect type

- Create, modify, and load inspection recipes

- Access production statistics and defect logs

Results and Impact

The implementation of the Rosepetal 360º system brought immediate benefits to the client’s production environment:

- 100% container inspection coverage

- Detection accuracy above 99.8% for curling, seam, and ear tab defects

- Automatic rejection of defective containers with real-time PLC control

- 40% reduction in manual inspection tasks

- No unplanned line stoppages after full integration

- ROI achieved in 10 months, driven by reduced waste and rework

✅ Key Results

- 8-camera 360º dual-plane inspection for complete coverage

- Detection of curling and triple-seam defects in real time

- Ear tab presence verification with instant feedback

- Seamless integration with PLC for defect ejection

- Configurable HMI panel for monitoring, tuning, and recipe management

Industry Significance

This project highlights how AI and vision technologies are transforming metal packaging quality control.

By combining multi-camera imaging, deep learning, and automation, Rosepetal AI helps manufacturers ensure flawless sealing integrity, traceability, and consistent quality, even at the highest production speeds.

Technologies applied: Deep learning, computer vision, multi-camera inspection, PLC integration, industrial automation

Sector: Metal packaging and manufacturing quality control

Client: Confidential (European packaging producer)

Solution: Rosepetal AI 360º Metal Container and Ear Tab Inspection System