360º AI Vision System for Cable Quality Inspection

A four-camera vision system for real-time inspection of cables, detecting geometric, surface, and conductor defects with AI precision in high-speed manufacturing lines.

Success Story: 360º AI Vision System for Cable Quality Inspection

In cable manufacturing, precision and consistency are critical to electrical performance and safety.

Even minor deviations in geometry or surface integrity can lead to defects, mechanical stress, or conductivity loss.

To address these challenges, a major cable manufacturer partnered with Rosepetal AI to implement a 360º computer vision inspection system powered by deep learning.

The Challenge

The client required a fully automated system capable of inspecting cables in real time as they exit the extrusion line.

Manual inspection was limited, subjective, and not scalable for continuous production. The goal was to detect and classify all critical defect types across the cable surface and conductor with absolute precision.

The defects to detect included:

Geometric or Dimensional Defects

- Necking (Narrowing): Reduction of the outer diameter due to tension or overheating.

- Bulging (Widening): Excess insulation material or extrusion irregularities.

- Ovalization: Non-circular cross-section caused by deformation or die misalignment.

- Conductor-Insulation Misalignment: Metal core not centered within insulation.

Surface Defects

- Stray Strands (Stacker): Loose filaments extending beyond insulation.

- Cracks or Fissures: Breaks in insulation due to poor extrusion or contaminated material.

- Wrinkles or Creases: Improper melt or irregular extrusion speed.

- Bubbles or Cavities: Air inclusions visible as translucent or raised areas.

- Burns or Discoloration: Excess temperature during extrusion or wire drawing.

Conductor Defects

- Partial Strand Cuts: Broken or incomplete filaments within the conductor.

- Contamination or Corrosion: Presence of oxidation, oil, or metallic residues.

Insulation or Coating Defects

- Lack of Adhesion: Insulation not properly bonded to the conductor.

- Particle Inclusions: Dust, metal, or foreign matter embedded in the plastic.

- Insulation Cuts or Nicks: Mechanical damage from tooling or handling.

The Solution: Rosepetal AI 360º Cable Inspection System

The system integrates four high-speed cameras arranged 90° apart to capture a complete 360º view of the cable surface as it moves along the line.

Using deep learning and image fusion, it analyzes each frame in real time to identify any geometric or surface anomalies.

1. Multi-Camera Geometry Reconstruction

A 3D profile of the cable is reconstructed from four synchronized camera feeds.

This allows detection of dimensional variations as small as ±0.05 mm, including ovalization and misalignment.

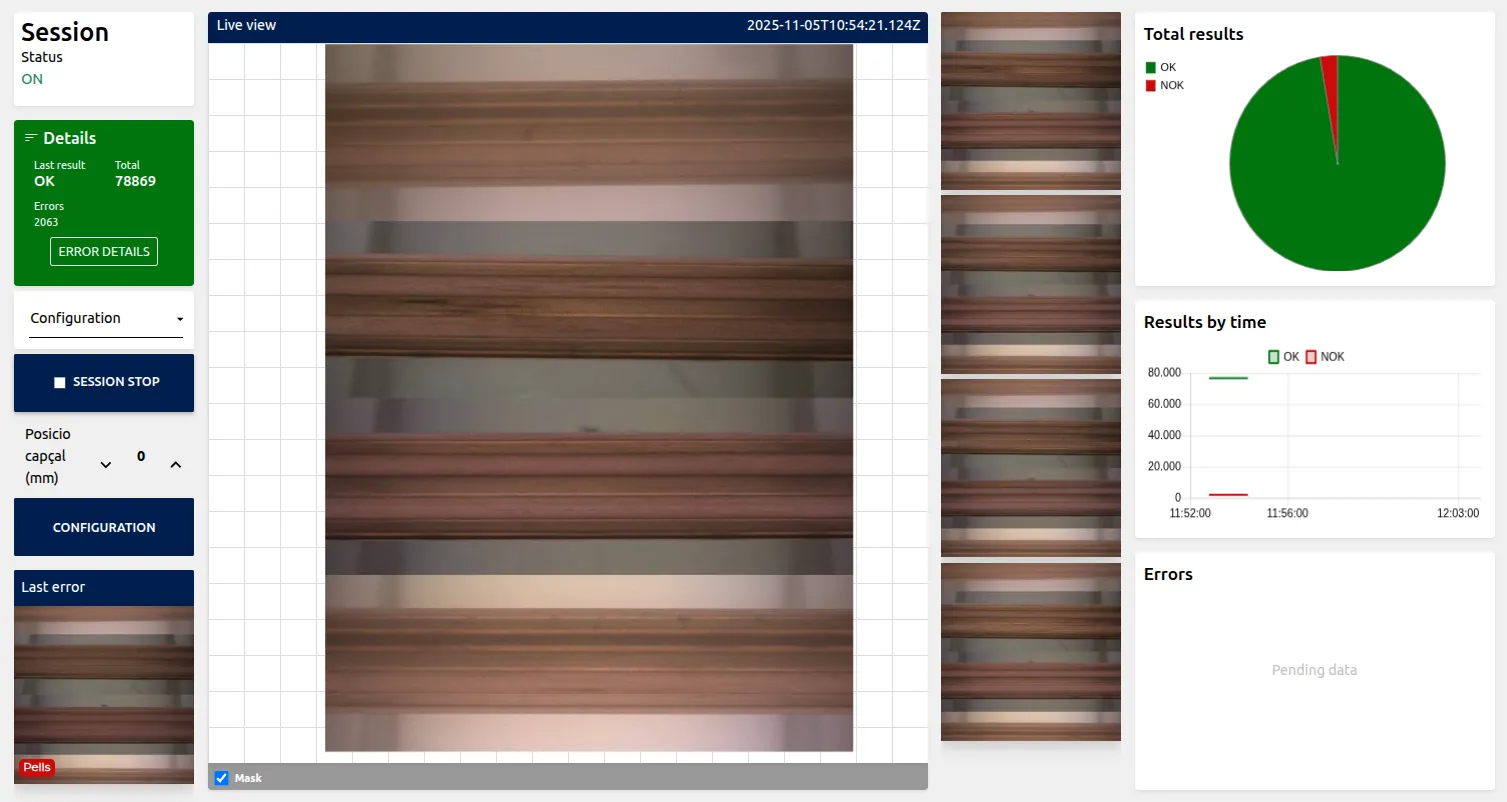

2. AI-Powered Surface Classification

A convolutional neural network (CNN) detects surface and insulation defects, classifying each into predefined categories such as crack, bubble, burn, or inclusion.

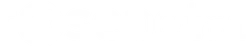

3. Real-Time Decision and Sorting

Defective sections are automatically marked for rejection or secondary inspection.

The system provides operators with live feedback via HMI dashboards, with defect images and location tracking.

4. Adaptive Learning and Traceability

The AI model continues to learn from new defect patterns, improving classification accuracy over time.

All inspection data and images are stored for traceability and statistical process control (SPC).

Results and Impact

After deployment, the manufacturer achieved substantial improvements in production quality and efficiency:

- 99.6% detection accuracy for all defect types

- 100% surface coverage with 360º inspection

- 30% reduction in scrap and rework

- Faster production speeds with no inspection bottleneck

- ROI achieved in 9 months through improved yield and fewer returns

The system now operates continuously, inspecting thousands of meters of cable per hour with AI-driven precision and zero downtime.

✅ Key Results

- Detection of geometric, surface, and conductor defects in real time

- 360º inspection with four synchronized cameras

- Automated defect classification and rejection

- Data logging and SPC integration for continuous improvement

- Improved product reliability and compliance with international standards

Industry Significance

This project demonstrates the potential of AI vision systems in manufacturing.

By combining multi-camera imaging, deep learning, and real-time analytics, Rosepetal AI enables cable producers to achieve zero-defect quality control — ensuring safer, more reliable, and globally compliant products.

Technologies applied: Deep learning, computer vision, 3D reconstruction, industrial automation, real-time defect classification

Sector: Cable manufacturing and extrusion quality control

Client: Confidential (European cable producer)

Solution: Rosepetal AI 360º Cable Quality Inspection System