AI Vision System for Weld Defect Detection in Automotive Manufacturing

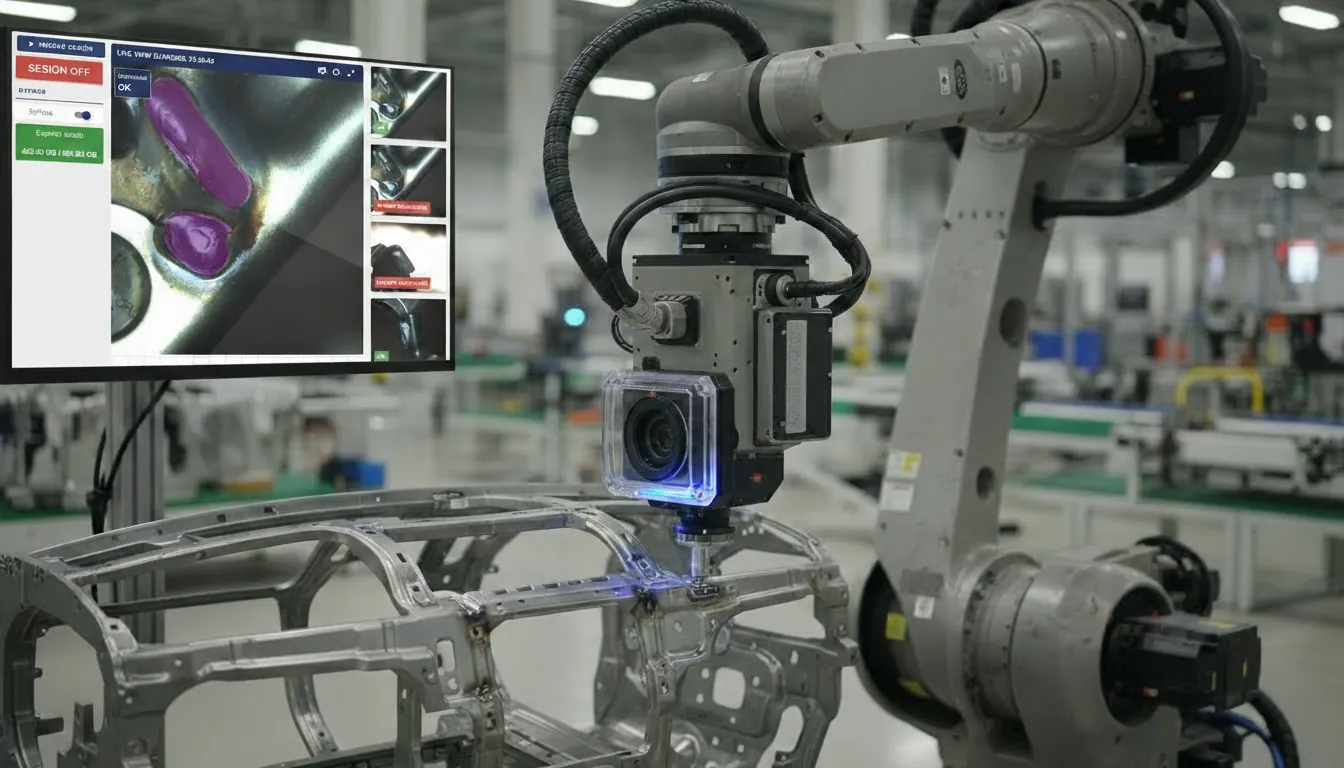

A deep learning vision system designed to inspect and classify weld quality in real time, detecting displacement, projections, perforations, undercut, and porosity with unmatched precision.

Success Story: AI Vision System for Weld Defect Detection in Automotive Manufacturing

In the automotive industry, weld quality directly impacts vehicle safety and performance. Even minor deviations in weld formation can lead to structural weaknesses, assembly failures, or aesthetic defects.

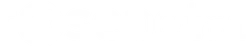

To eliminate these risks, a major automotive manufacturer partnered with Rosepetal AI to deploy an AI-powered computer vision system capable of detecting and classifying weld defects in real time.

The Challenge

Manual or offline inspection of welds was no longer viable for modern production speeds.

The client needed a system that could:

- Inspect every weld seam in real time, without slowing down production

- Detect multiple types of welding defects automatically

- Provide instant traceability and visual confirmation of any anomalies

- Reduce rework and scrap rates while ensuring compliance with OEM quality standards

The Solution: AI-Powered Weld Quality Analysis

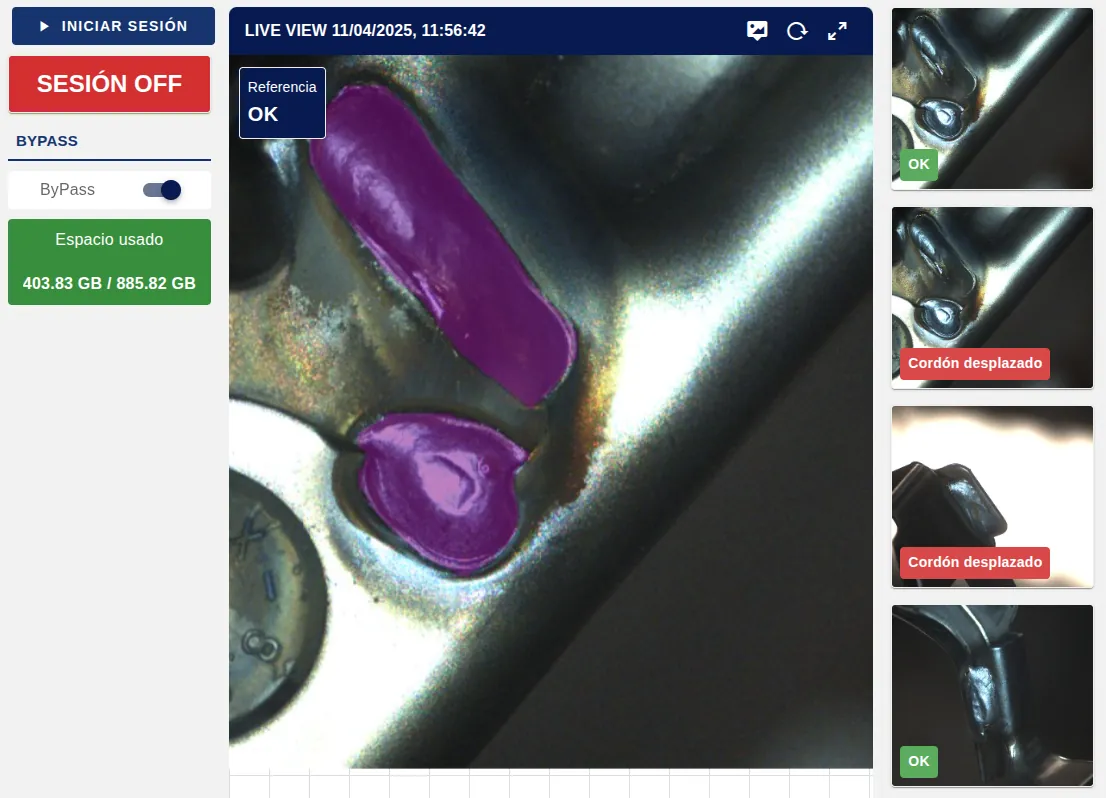

Rosepetal developed a deep learning vision system trained to identify and classify five critical types of weld defects.

Each weld seam is captured by high-resolution cameras and analyzed instantly by neural networks optimized for metallic textures, reflections, and lighting variability.

1. Cord Displacement (Misaligned Weld Bead)

The system detects when the weld bead deviates from the joint’s ideal axis.

By analyzing geometric symmetry and thermal patterns, it flags offsets greater than 0.5 mm, ensuring consistent structural integrity.

Detected indicators:

- Lateral displacement of the bead

- Visible asymmetry with respect to the joint line

2. Projections (Spatter)

Using reflectivity and morphology analysis, the AI identifies small metallic droplets expelled during welding that solidify near the seam.

Detected indicators:

- Irregular spherical or shiny particles near the weld

- Bright reflections outside the main bead path

3. Perforations (Burn-Through)

The system detects holes or areas where the base metal has melted through, a severe defect compromising structural resistance.

Detected indicators:

- Circular or irregular openings

- Burned or darkened zones around the weld

4. Undercut (Edge Groove)

Through 3D surface reconstruction, the AI identifies continuous grooves or depressions at the edge of the bead caused by excessive energy or improper electrode angle.

Detected indicators:

- Thin continuous channels along the weld edge

- Rough surface with visible shadow patterns

5. Porosity (Cavities)

Deep learning models trained on thousands of examples detect small gas inclusions or voids on or below the surface of the weld bead.

Detected indicators:

- Rounded cavities visible on the surface

- Low-density areas in X-ray or ultrasound imaging

Results and Impact

After integrating the Rosepetal AI inspection system, the client achieved measurable improvements across quality and efficiency metrics:

- 99.95% weld defect detection accuracy

- Zero structural failures attributed to undetected weld defects

- Reduction of manual inspection time by 60%

- 20% decrease in weld rework and scrap

- Full traceability of weld images and classifications for every part produced

The system operates fully integrated with the robotic welding line, enabling real-time alarms, defect classification, and automated data logging.

✅ Key Results

- Detection and classification of five major weld defect types

- Real-time inspection at full production speed

- Automatic integration with robotic welding control systems

- Improved structural reliability and reduced rework

- Comprehensive digital traceability for all welds

Industry Significance

This project demonstrates how AI vision systems are revolutionizing quality control in automotive manufacturing.

By combining deep learning, high-speed imaging, and real-time data analytics, Rosepetal AI helps manufacturers achieve zero-defect welding—boosting safety, efficiency, and confidence in every vehicle produced.

Technologies applied: Deep learning, computer vision, industrial inspection, 3D surface reconstruction, real-time classification

Sector: Automotive manufacturing and metal fabrication

Client: Confidential (OEM automotive supplier)

Solution: Rosepetal AI Weld Defect Detection and Classification System